The cost of constructing a small 300,000 gallon (1 million liters) water tower is around $300,000-$400,000 depending on native situations and materials used. Water tower top varies fairly a bit throughout the United States and even inside cities. You also can expect to pay around $400 and $1,800 per ton for metal. At about 2.2 pounds of steel per square foot of concrete foundation or base, that price provides up rapidly. That piping will embody digging over 400 feet of trench, laying the pipe, and then operating the pipe up the water tower.

This is the owner’s assurance that a metal tank will carry the workload as soon because the last plate is welded. And it'll proceed to take action, even under weathering and conditions of service and stress that may be trigger for grave concern if the tank had been constructed of some other material. For over one hundred years, corrugated galvanized steel tanks have been the preferred selection for safe, dependable, and cost-effective water storage. In addition to manufacturing tanks for over forty years, American Tank can also be a General Engineering Contractor that's licensed to construct tanks and foundations in California, Nevada, and Washington.

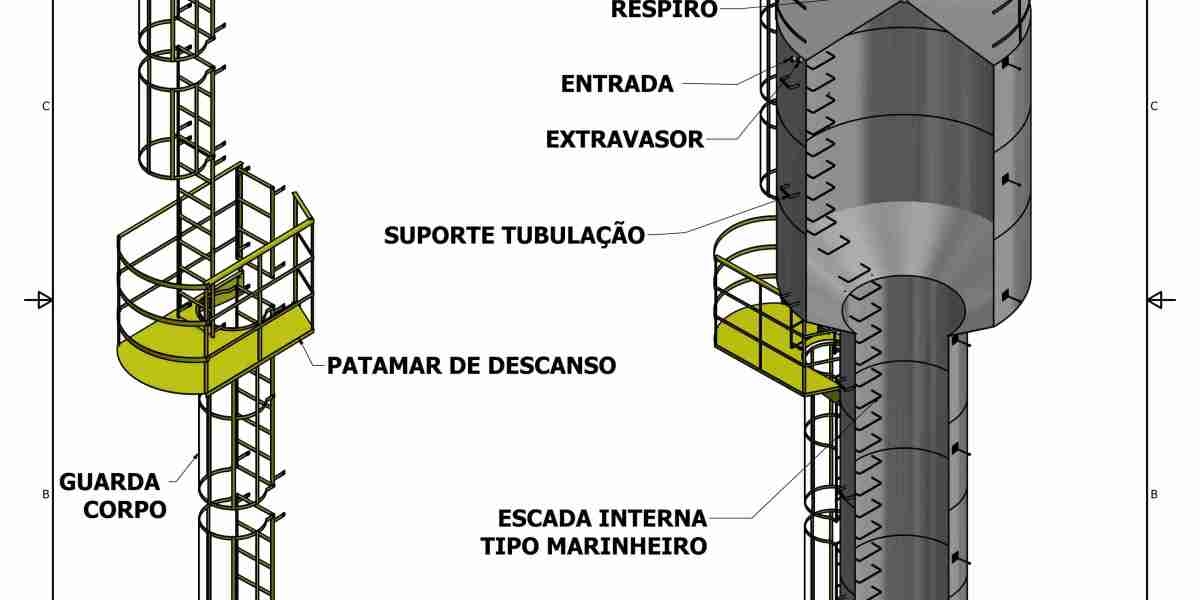

Roof Access Hatch & Ladder

The quantity of storage required, the native topography, and system pressure should all be analyzed in making this choice. All metal plate is manufactured to American Society for Testing and Materials (ASTM) Standards, a national set of specs. These standards are revised periodically to report new specifications and adjustments to present ones. Mill test reviews are available for each piece of steel that is manufactured within the United States. The numerous diameters and head ranges for those shown within the accompanying diagrams and tables are only consultant, and should range with individual fabricators. Specific diameter/head vary combos must be determined by the tank fabricator within the limits indicated in the tables.

From the fashionable Nexus to the transitional Aquia IV to the classic Connelly, we offer a broad array of beautiful designs that work with any aesthetic. TOTO’s market-leading TORNADO Flushing System options two highly effective nozzles that create a centrifugal, cyclonic rinsing motion that reduces waste buildup, keeping the bowl cleaner. Using only 1.zero or 1.28 gallons per flush (gpf), this high-efficiency flush system is simpler in one flush than most bathrooms are with a quantity of flushes. Contemporary fashion bogs embrace minimalism, offering a chic, edited aesthetic that focuses on simplicity and performance.

Aquamate’s tank panels are lined with a galvanized coating that’s 1.45 ounces per sq. foot (G145) – the thickest marketed coating in the marketplace. By using lightweight thin-gauge steel panels, Aquamate’s metal water tanks have all the required power to withstand water, snow and seismic loads without the excess material cost. Welded steel water storage tanks fulfill the 4 primary standards of low price, reliability, versatility and availability. Steel constructions can be constructed in a wide selection of shapes, limited only by the imagination of the designer. The three major classes of storage tank design are reservoirs, standpipes or elevated tanks. In addition, https://together-19.com/read-blog/70624_reservatorio-elevado-entenda-sua-importancia-e-funcionamento-no-abastecimento-De.html special tank designs are more and more requested by end users.

A complete range of additional and over-size fittings

Because of their peak and supporting structure, elevated tanks provide nearly limitless possibilities for engaging design. Steel’s power and caixa d água tipo taça 15000 Litros flexibility make it the natural material for development of safe, economical and eye-catching structures. When choosing a water storage tank to fill the wants of a city or business, a comprehensive evaluation ought to be made from all of the alternate designs available. Members of the Steel Tank Institute/Steel Plate Fabricators Association (STI/SPFA) give necessary components, such as potential service and financial issues, the cautious attention they deserve. The standpipe’s flat backside, just like the reservoir’s is not designed to hold stress. It acts as an impervious, flexible membrane that assures dependable, "bottle-tight" construction.

Typical Steel Water Storage Reservoirs

A reservoir, a tank with a diameter larger than its peak, is a typical type of water storage structure. Of the three types of steel water tanks, a reservoir usually is essentially the most economical to manufacture and erect due to its low peak and relative simplicity. All materials utilized in its construction are subjected to rigid examination. Its erection is carried out to a longtime standard by a proven technique. Its performance characteristics shall be predictableon the day it is completed and after 10 years of service.

The form of the roof may be conical, toriconical, dome or ellipsoidal, with or with out decorative trim. Standard equipment could include shell and roof manholes, a roof vent, painter’s trolley rail, fastened outdoors ladder, and connections or pipes as required. Inside ladders aren't beneficial in areas where sustained freezing climate may be anticipated. Other than the loading from the tank filled with water, there are three hundreds that should be thought-about in the design of a tank-wind, snow and earthquake. Wind load typically relies on an assumed wind velocity of one hundred MPH, although the next velocity is utilized in some cases.