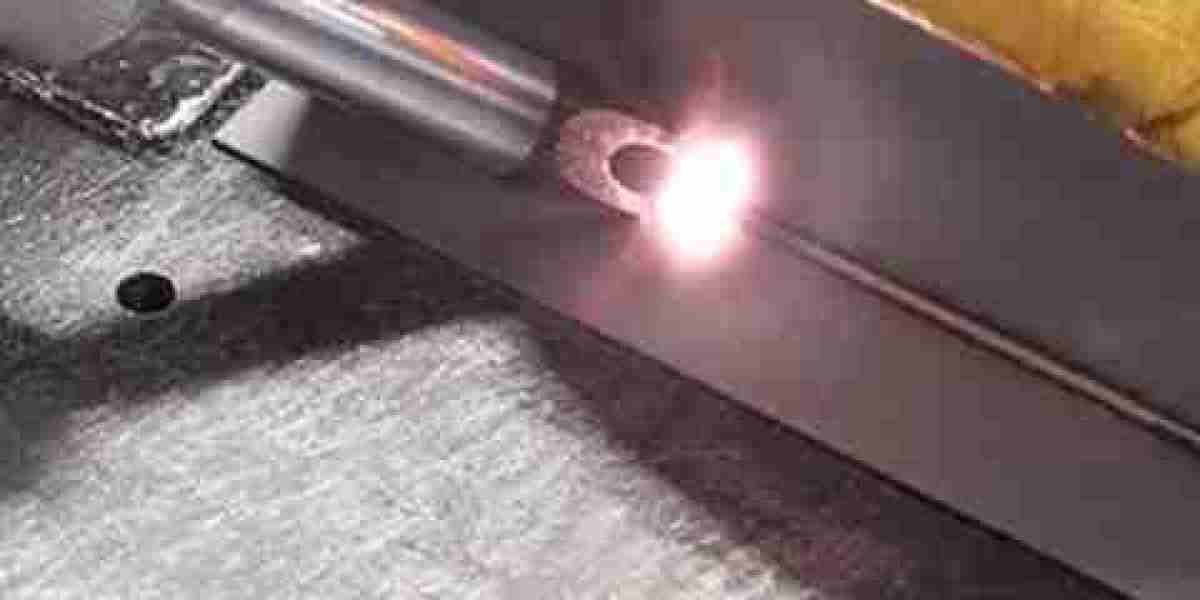

In the world of modern manufacturing, precision, efficiency, and innovation are paramount. LaserChina, a leading name in laser technology, has carved its niche as a pioneer in developing advanced laser cutting welding machine. These machines are transforming industries, enabling businesses to achieve unparalleled quality and speed in their operations.

What Sets LaserChina Apart?

LaserChina stands out as a reliable provider of state-of-the-art laser solutions. The company specializes in manufacturing machines that cater to a wide array of industrial applications, including automotive, aerospace, construction, electronics, and more. Here’s why LaserChina has become a top choice for businesses:

Precision Engineering:

LaserChina’s machines deliver exceptional precision, ensuring that every cut and weld meets the highest quality standards. This level of accuracy is critical for industries where even the smallest deviations can lead to significant losses.Innovative Technology:

The brand incorporates cutting-edge technology, including AI-driven controls and automated features, to streamline processes. These advancements enhance productivity while minimizing errors.Versatile Applications:

Whether it’s intricate designs in metal sheets or sturdy welds in heavy machinery, LaserChina’s machines are versatile enough to handle a variety of materials and tasks with ease.Energy Efficiency:

With sustainability becoming a priority, LaserChina designs its machines to be energy-efficient, reducing operational costs and environmental impact.Exceptional Support:

From installation to maintenance, LaserChina provides comprehensive support to its clients, ensuring smooth operations and maximum ROI.

Features of Laser Cutting and Welding Machines

The laser cutting and welding machines from LaserChina are a blend of advanced features that cater to modern manufacturing needs:

- High-Speed Performance: Achieve faster production rates without compromising on quality.

- User-Friendly Interfaces: Easy-to-use control panels make operations simpler for technicians.

- Compact Designs: Save valuable factory floor space with machines designed for optimal use of space.

- Material Flexibility: Handle materials like stainless steel, aluminum, copper, and alloys seamlessly.

- Customizable Options: Tailor machines to specific needs, ensuring maximum efficiency.

Applications Across Industries

LaserChina’s machines are reshaping various industries:

- Automotive Manufacturing: Precise welding for car parts and intricate designs for decorative components.

- Aerospace Industry: High-precision cutting and welding for components subjected to extreme conditions.

- Electronics: Fabrication of small, detailed parts used in circuit boards and gadgets.

- Construction: Strong and durable welding for structural elements.

- Jewelry Design: Intricate cutting for high-end, custom jewelry pieces.

Why Businesses Choose LaserChina

- Cost-Effectiveness: Investing in a LaserChina machine ensures a significant reduction in production time and waste.

- Improved Quality: Superior technology results in flawless products, enhancing brand reputation.

- Global Reach: LaserChina’s presence in international markets ensures consistent support and product availability.

The Future of Laser Technology

As industries continue to evolve, LaserChina remains committed to innovation. With a focus on integrating AI, IoT, and sustainability into their machines, the company is poised to lead the next wave of advancements in laser cutting welding machine technology.

For businesses looking to stay ahead in the competitive landscape, partnering with LaserChina is a step toward excellence.