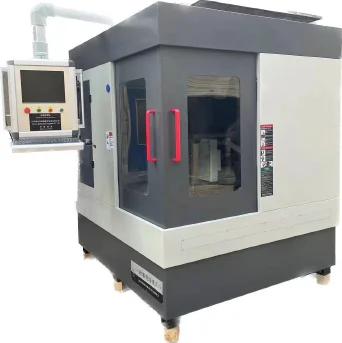

Taizhou Dongqi CNC Equipment Co., Ltd.'s vertical diamond cutting CNC machine tools are essential in various industries, particularly in precision machining and manufacturing. These machines are designed to deliver high accuracy and efficiency when cutting hard materials like stone, ceramics, and composites. However, operating these machines requires specific skills and adherence to safety precautions to ensure optimal performance and safety.

Understanding the Machine

Familiarization with Components

Before operating a vertical diamond cutting CNC machine, it is crucial to understand its components. Key parts include the spindle, tool holder, coolant system, and control panel. Familiarity with these components allows operators to troubleshoot issues quickly and maintain the machine effectively.

Software Proficiency

Operators must be proficient in the CNC software used to program the machine. This includes understanding how to input cutting parameters, tool paths, and other necessary settings. Mastery of the software not only enhances productivity but also minimizes the risk of errors during operation.

Essential Operating Skills

Precision Measurement

Accurate measurement is fundamental in CNC machining. Operators should be skilled in using measuring tools such as calipers and micrometers to ensure that the dimensions of the workpiece meet specifications. This skill is vital for maintaining quality control and achieving the desired finish.

Tool Selection and Maintenance

Choosing the right diamond cutting tool is critical for successful machining. Operators should understand the different types of diamond tools available and their specific applications. Regular maintenance of tools, including sharpening and cleaning, is also essential to prolong their lifespan and maintain cutting efficiency.

Programming and Setup

Setting up the machine involves loading the correct program, securing the workpiece, and calibrating the tool. Operators should be adept at reading technical drawings and translating them into machine programs. Proper setup minimizes downtime and ensures a smooth cutting process.

Safety Precautions

Personal Protective Equipment (PPE)

Safety should always be a priority when operating CNC machines. Operators must wear appropriate PPE, including safety glasses, gloves, and ear protection. This equipment protects against potential hazards such as flying debris and excessive noise.

Machine Safety Checks

Before starting the machine, operators should conduct thorough safety checks. This includes inspecting the machine for any signs of wear or damage, ensuring that all safety guards are in place, and verifying that the coolant system is functioning correctly. Regular maintenance checks can prevent accidents and prolong the machine's lifespan.

Emergency Procedures

Operators must be familiar with emergency procedures in case of a malfunction or accident. This includes knowing how to quickly shut down the machine and understanding the location of emergency stops. Training in first aid and emergency response can also be beneficial in ensuring a safe working environment.

Conclusion

Operating vertical diamond cutting CNC machine tools requires a combination of technical skills and safety awareness. By mastering the essential operating skills and adhering to safety precautions, operators can enhance productivity and ensure a safe working environment. Continuous training and practice are vital for maintaining proficiency and adapting to advancements in technology. As industries continue to evolve, the importance of skilled operators in maximizing the potential of CNC machines cannot be overstated.