These tanks may be outfitted with a 16″ stainless-steel mesh tank screen put in on the top of the tank to find a way to create a rainwater harvesting tank. It’s main job is to maintain tree particles and leaf litter from getting into the tank. The ultrasonic pulse is shipped to the liquid to be measured, and then the reflected sign is received. The sensor is powered by an influence adapter or a photo voltaic panel, installed on the top of the water tank, and reservatório tipo taça dwg uses a non-contact measurement technique with excessive accuracy. In addition to those purposes, the customizable nature of truck tanks offers extra advantages. Your water needs during a civil engineering project could be considerably diversified. One moment they’re for ingesting, another for mud suppression, or fireplace safety.

Diverse Construction Needs

After the tank is constructed, a paint/epoxy lining is applied to the inside of the tank to offer a protecting barrier between the water and reservatório tipo taça dwg the steel itself. This product is FDA permitted for potable (drinking) water functions and is ANSI / NSF sixty one certified. Each tank is tested at the manufacturing facility to make certain that it's watertight. With virtually 90 years of history, these tanks have a typical lifespan of 30 – 35 years. Our metal water tanks can be found in 9 normal sizes, from 130″ to 512″ diameter, supplying you with a spread of sizes and volumes to swimsuit your house, business, ranch or farm’s necessities. Truck water cartage tanks play a pivotal part in civil engineering tasks. They fulfill the need for water supply in remote building websites.

Designed to transport considerable volumes of water, these tanks are essential for resource allocation. Selecting the proper tank is critical as each project has unique requirements. Capacity and material high quality are essential factors in making your selection. Their operate just isn't constricted to solely water transportation; they'll carry different substances too. To know more concerning the tanks’ versatility, you could think about checking the Forbes Group. Maintaining hydration for staff, facilitating excavation processes, or controlling dust are some benefits of truck tanks in project websites.

Designed to transport considerable volumes of water, these tanks are essential for resource allocation. Selecting the proper tank is critical as each project has unique requirements. Capacity and material high quality are essential factors in making your selection. Their operate just isn't constricted to solely water transportation; they'll carry different substances too. To know more concerning the tanks’ versatility, you could think about checking the Forbes Group. Maintaining hydration for staff, facilitating excavation processes, or controlling dust are some benefits of truck tanks in project websites.Aquamate’s tank panels are coated with a galvanized coating that’s 1.45 ounces per sq. foot (G145) – the thickest marketed coating in the marketplace. By utilizing lightweight thin-gauge steel panels, Aquamate’s metal water tanks have all of the required power to resist water, snow and seismic hundreds with out the surplus material value. The West Coast Poly 23,000L Round Water Tank is a strong, high-capacity possibility designed for Australian properties in search of dependable rainwater storage. With a 23,000-litre capability, it’s best for larger backyards, interest farms, or rural settings, offering a dependable source of water for garden irrigation, family supply, or livestock wants. This tank fits properly beside sheds, garages, or paddocks, and its sturdy development ensures it withstands the powerful Australian climate.

Year "No Service Cost" Warranty

They let you give attention to the task at hand with out steady supervision. The tank has both a ¾", 1¼", or 2″ bulkhead fitting on the backside to get water out of the tank.

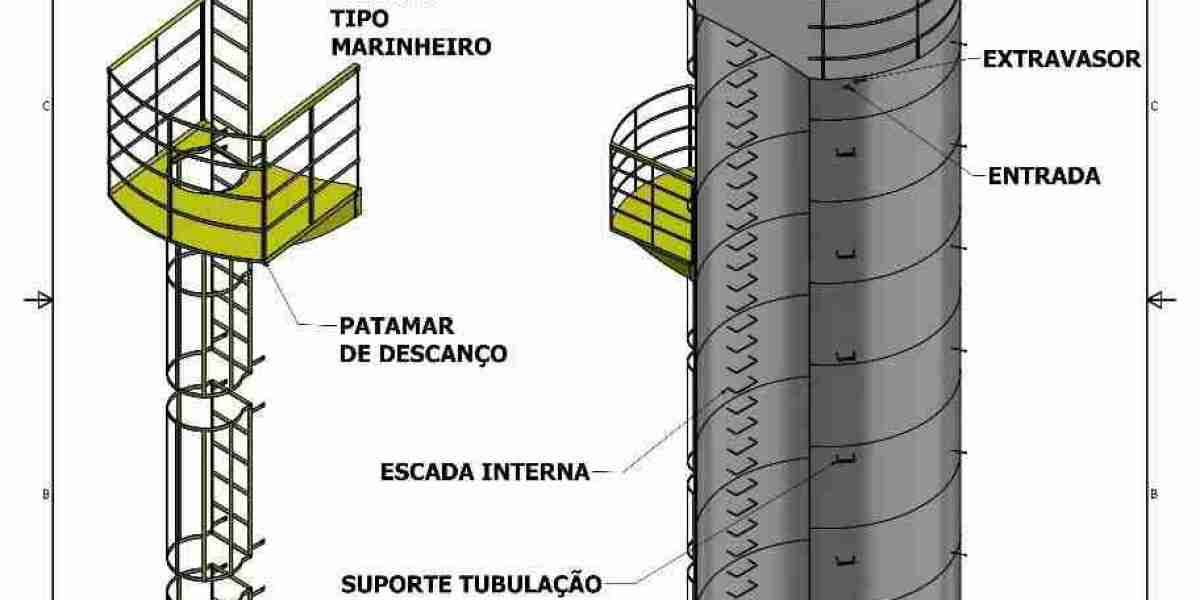

No metal floor is needed, as the concrete basis turns into the floor of the tank. The tank walls are seismically anchored to the inspiration as needed. Supports the Flexible Membrane NSF61 licensed and Geotextile Pre-liner system. Sheets range in gauges relying on the engineering calculation for a particular tank. This relies on the usable gallon requirement, project coordinates, and tank use/application. Each receptacle contains a stainless steel filter, mud cover and overflow equipment. Long-haul truck drivers appreciate the reliability of these tanks for water transportation, guaranteeing their utility on numerous construction tasks.

If you don’t see the size you need – we will quote any tank up to 650,000 gallons

Make probably the most of rainwater assortment with a tank constructed to ship long-term water safety and peace of mind. For over a hundred years, corrugated galvanized metal tanks have been the popular selection for protected, reliable, and cost-effective water storage. In addition to manufacturing tanks for over forty years, American Tank can also be a General Engineering Contractor that's licensed to build tanks and foundations in California, Nevada, and Washington. All our tanks include Wet-Stamped Engineering and are installed onsite by our own manufacturing facility licensed set up crew. Many of our tanks may even be put in on a simple gravel ring basis with out the need for expensive concrete foundations and costly sitework. Are you concerned in major civil engineering projects and battling efficient water cartage? You might be coping with ineffective transport, storage, or distribution techniques disrupting your project timelines.