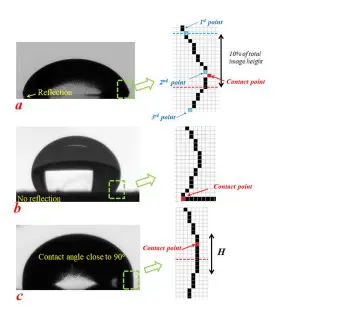

Surface energy is a fundamental concept in materials science and engineering that involves the interaction between solid surfaces and liquids. It plays a critical role in various industrial applications, influencing processes those industries rely on. From pharmaceuticals that require precise formulation to aerospace engineering where performance is paramount, the understanding and manipulation of surface energy can significantly enhance product efficacy and manufacturing efficiency. Droplet Lab, founded in 2016 by Dr. Alidad Amirfazli, alongside his researchers Dr. Huanchen Chen and Dr. Jesus L. Muros-Cobos, has emerged as a leading innovator in harnessing the principles of surface energy to improve industry outcomes.

The Fundamentals of Surface Energy

At its core, surface energy refers to the amount of excess energy at the surface of a material compared to its bulk. The Surface Energy Measurement Software largely pertain to molecular interactions, where some molecules at the surface possess different characteristics than those in the interior. In practical terms, materials with high surface energy are typically hydrophilic, meaning they have a strong affinity for liquid water, while low surface energy materials are hydrophobic, repelling water. This fundamental understanding of surface energy can be pivotal for controlling wetting, adhesion, and spreading processes across various materials, ultimately governing the performance of products ranging from medical devices to airplane components.

Pharmaceutical Applications

In the pharmaceutical industry, surface energy plays a vital role in the formulation of drugs. The effectiveness of a drug often hinges on its ability to dissolve and be delivered into the body efficiently. Therefore, controlling surface energy can enhance the solubility and bioavailability of pharmaceutical compounds. By modifying the surface properties of drug formulations, Droplet Lab has succeeded in creating better delivery systems for active ingredients, improving the overall therapeutic outcomes of medications. In designing emulsions, for instance, the ability to manipulate surface energy enables pharmaceutical companies to optimize formulation stability and control release kinetics, aligning with stringent industry standards and overcoming challenges like solubility and stability.

Impact on Coatings and Adhesives

Beyond pharmaceuticals, the influence of surface energy is starkly evident in the realm of coatings and adhesives. In many industries, including automotive and construction, the adherence of paint and coatings is critical to both functionality and aesthetics. Achieving an optimal bond between varied surfaces demands a comprehensive understanding of surface energy. Droplet Lab's innovations have led to advanced surface treatments that modify the energy characteristics of substrates without compromising their inherent properties. By improving the wetting and spreading dynamics of coatings, manufacturers can ensure a more durable bond that withstands environmental stressors. Moreover, their research supports the development of environmentally friendly adhesives that function effectively on low surface energy materials, thus expanding potential applications in green technologies.

Aerospace Innovations

In the aerospace sector, the importance of surface energy extends to the performance and safety of aircraft. Engineers must ensure that various materials interact seamlessly within the complex design of an airplane, where factors such as weight, fuel efficiency, and durability deeply intersect. For instance, surface energy influences not only the adhesion of coatings that protect against corrosion but also the characteristics of fuel and fluid flow across surfaces. Advanced treatments and coatings that optimize surface energy can contribute to drag reduction and fuel efficiency, central to aerospace development. Through groundbreaking research, Droplet Lab is pioneering methods that enhance energy efficiency and performance for aircraft components, contributing positively to sustainability efforts in an industry facing increasing regulatory pressures concerning emissions.

Future Directions and Industry Relevance

The relevance of surface energy in industrial applications cannot be understated. It is a powerful indicator that influences product formulation, material selection, and manufacturing processes across various sectors. As industries continue to evolve, researchers like those at Droplet Lab are at the forefront, investigating advanced methodologies that could unravel new potential applications while addressing environmental concerns. Future applications may explore nanotechnology’s role in surface energy manipulation or the development of self-cleaning materials, which could revolutionize industries where cleanliness and sterility are critical, such as in healthcare and food processing.

Conclusion

In conclusion, surface energy remains an essential area of research and application across numerous industries. The efforts of Droplet Lab exemplify how a deeper understanding of surface energy can lead to substantial advancements in product performance and manufacturing efficiency. As challenges such as environmental sustainability and technological innovation continue to shape the industrial landscape, the insights provided by existing and future research on surface energy will be invaluable in guiding progress. Ultimately, the continuous exploration of this field promises to offer increasingly effective solutions, enhancing productivity and safety across diverse sectors from pharmaceuticals to aerospace.