One of the essential methods for preventing accidental damage to these installations is the use of specialized warning tape. This article focuses on Underground Warning Tape Specification, delving into its importance, types, and applications while shedding light on manufacturers and suppliers who play a crucial role in providing this safety measure.

Importance of Warning Tape in Construction

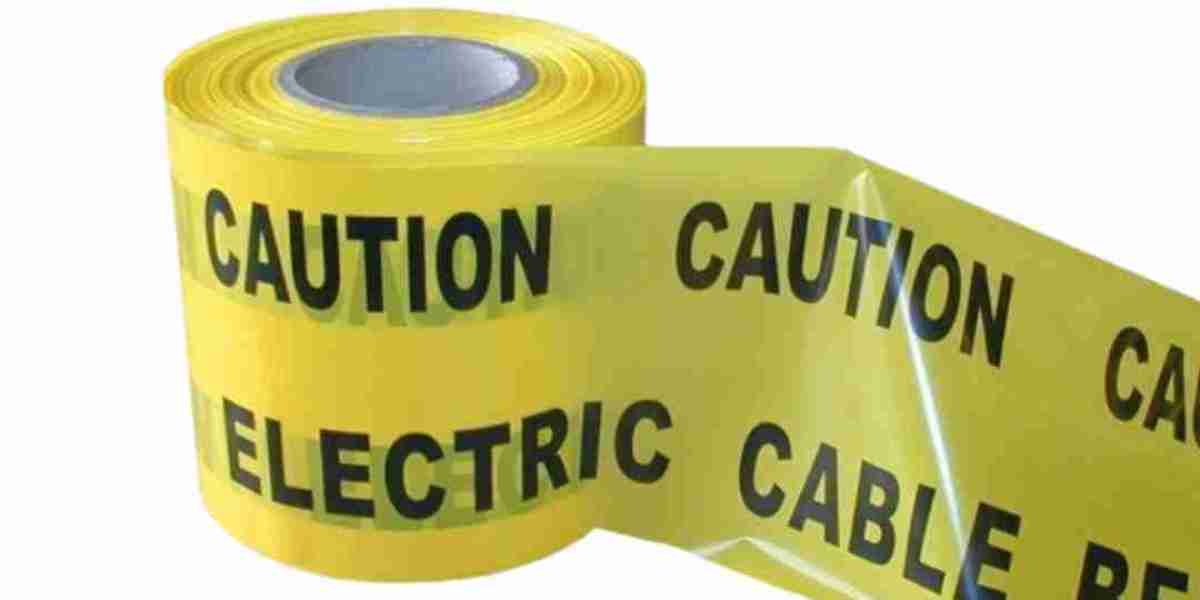

In construction or maintenance projects, a single mistake can lead to hazardous consequences. A misplaced shovel strike or unexpected excavation can sever vital utility lines, leading to extensive disruptions, injury, and costly repairs. Underground Warning Tape serves as a visual deterrent, alerting workers and other stakeholders about potential hazards lying below the surface. This instantly recognizable tape, often colored and labeled for specific utilities, plays a crucial role in mitigating risks and ensuring safety during digging and construction activities.

Types of Underground Warning Tape

When it comes to Underground Warning Tape, not all are created equal. Various types of tapes are available, each catering to specific needs and environments. There are standard tapes typically used for marking underground electrical lines, gas pipelines, or communication cables. These may come in color-coded variations, such as yellow for gas lines, red for electric, and blue for potable water. The tape's material can also vary, with some being more suitable for long-term underground exposure and others optimized for temporary warnings. Understanding the distinct types available ensures that construction teams can choose appropriately based on the needs of the project.

Material and Durability Specifications

The Underground Warning Tape Specification is crucial in determining the longevity and efficacy of the tape. The most common materials include polyethylene and PVC, chosen for their robustness and resistance to elements such as moisture, chemicals, and soil erosion. A quality tape should withstand the pressures of being buried underground while maintaining its visibility over time. Durability is further enhanced by the inclusion of specific colors and symbols, which make it easy to identify the type of utility line and warn against potential hazards. Understanding these specifications not only aids in compliance with safety regulations but also optimizes the lifespan of the warning tape.

Choosing the Right Underground Warning Tape

Selecting the right supplier can significantly impact the quality of products used in a project. An established Underground Warning Tape Manufacturer is expected to have a good reputation, quality certifications, and a history of supplying quality tape that meets industry standards. When evaluating potential manufacturers, consider aspects such as production techniques, material sourcing, and commitment to innovation. Additionally, customer reviews and case studies can provide insight into a manufacturer's reliability and the effectiveness of their product offerings.

Customization Options for Unique Needs

Many projects may require custom solutions beyond standard tape offerings. An effective Underground Warning Tape Supplier can provide tailored options suited to individual project requirements. This might include custom lengths, widths, or printing specific to a project or client needs. Custom tapes can often display essential information such as installation dates, utility company names, or even QR codes linked to more detailed utility maps. This not only enhances visibility but also fosters better communication among different teams working in the field.

Regulatory Compliance and Best Practices

Adhering to regulatory standards is a vital component of any excavation project. The use of Underground Warning Tape comes with specific guidelines that vary by region and governing bodies. Understanding these regulations is crucial as they define the required specifications for the tape, its placement, and its effective use. Best practices also dictate that the tape be placed at a specific depth above the utility line, which can vary based on local regulations. Following these guidelines helps ensure that civil liabilities are minimized and enhances the safety of everyone involved in the project.

Conclusion: Invest in Quality Warning Solutions

In conclusion, the value of implementing effective underground safety measures cannot be overstated. Utilizing high-quality Underground Warning Tape is a practical and intelligent investment for any construction or excavation project. Choosing a reliable Underground Warning Tape Supplier is essential for ensuring compliance with safety standards and obtaining the right products for specific needs. Properly marking underground utilities enhances overall safety and prevents accidents that could lead to costly damage. The imperative choice of warning tape, customization, and adherence to regulations guarantees that projects proceed smoothly and efficiently.

Frequently Asked Questions

What should I look for in Underground Warning Tape?

When choosing Underground Warning Tape, look for durability, clarity in markings, compliance with safety standards, and specific color coding for different utilities.

How long does Underground Warning Tape last underground?

The lifespan of underground warning tape largely depends on the material used, environmental conditions, and soil composition. Generally, high-quality tapes can last several years.

Can I use standard tape for underground marking?

It is not advisable to use standard tape for underground markings, as they may not be designed to withstand environmental factors or provide the necessary warnings required by regulations.

What is the typical width of Underground Warning Tape?

The typical width ranges from 3 to 6 inches, but customization is often available to meet specific project needs.