Geonets, an essential component in modern engineering and environmental management, have gained immense popularity due to their versatility and effectiveness. Whether you are in the construction industry or looking for innovative ways to manage environmental challenges, geonets offer a robust solution. This comprehensive guide explores what geonets are, their applications, benefits, and answers to some commonly asked questions to give you a well-rounded understanding.

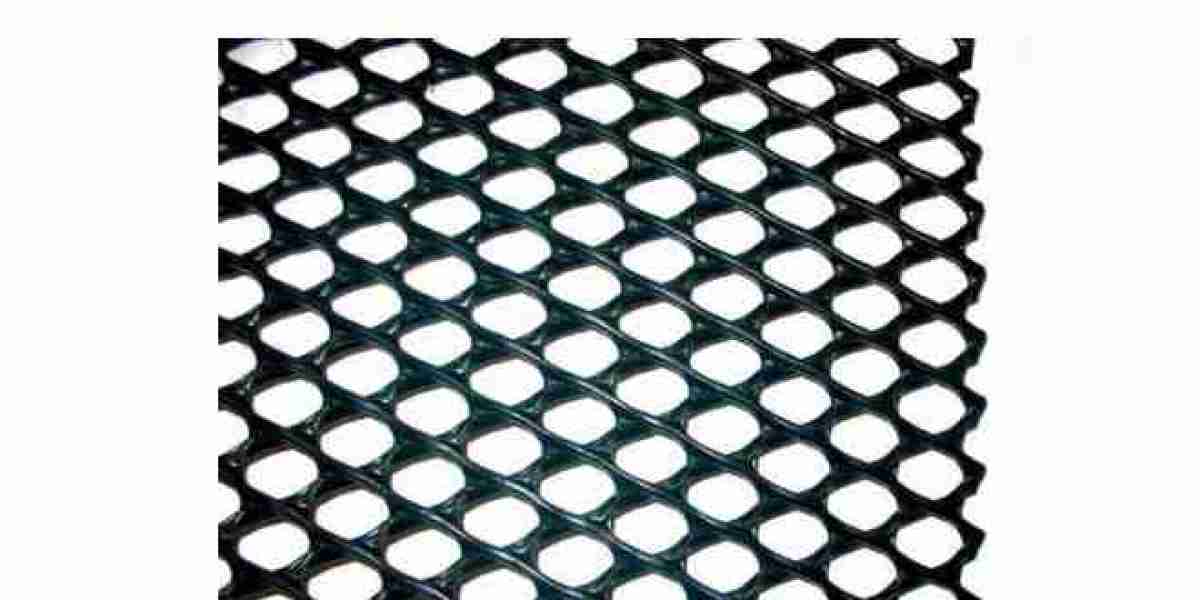

A geonet is a geosynthetic material made Pulkit Plastic Products from high-density polyethylene (HDPE) or polypropylene. It features a net-like structure designed for various engineering and environmental applications. This material is lightweight, durable, and resistant to chemicals, UV radiation, and temperature fluctuations, making it a preferred choice in diverse fields.

The primary purpose of a geonet is to facilitate drainage and reinforcement, offering a reliable way to manage water flow, control erosion, and stabilize structures. These properties make geonets indispensable in construction, agriculture, and waste management projects.

Applications of Geonet

1. Drainage Systems

One of the most common uses of Geonet in road construction is in drainage systems. Their unique structure efficiently channels water away from structures, reducing hydrostatic pressure and preventing waterlogging. Geonets are often used in road construction, retaining walls, and landfill covers to ensure proper drainage.

2. Erosion Control

Geonets are highly effective in stabilizing soil and preventing erosion. They are widely used in slopes, riverbanks, and embankments to minimize the impact of water and wind, thus preserving the integrity of the landscape.

3. Landfill Management

In landfills, geonets act as drainage layers to manage leachate and gas. They prevent contamination of surrounding soil and water bodies by providing efficient collection and channeling systems for hazardous waste.

4. Agriculture

In agricultural settings, geonets are used for water management in irrigation systems. They help in evenly distributing water, reducing wastage, and ensuring optimal soil hydration.

5. Foundation Reinforcement

Geonets provide additional stability to foundations by distributing loads evenly and preventing subsidence. This application is particularly useful in areas with weak or unstable soil.

1. Durability and Longevity

Geonets are made from high-quality materials that ensure they can withstand harsh environmental conditions. Their resistance to chemicals and UV radiation ensures a long lifespan.

2. Cost-Effective

Despite their advanced functionality, Geonets for highway construction are relatively affordable. Their installation and maintenance costs are low, making them an economical choice for large-scale projects.

3. Environmentally Friendly

By preventing erosion, managing waste, and optimizing water usage, geonets contribute to environmental sustainability. Their inert materials do not leach harmful substances, ensuring safety for ecosystems.

4. Versatility

The wide range of applications makes geonets a versatile solution for many industries. Whether you need drainage, reinforcement, or erosion control, geonets can be adapted to meet specific project requirements.

Proper installation is crucial to maximize the effectiveness of a geonet. Here is a step-by-step guide:

Site Preparation

Clear the area of debris, vegetation, and irregularities.

Ensure the surface is smooth and stable.

Positioning the Geonet

Roll out the geonet on the prepared surface.

Align it properly according to the project’s specifications.

Securing the Geonet

Use anchors or pins to hold the geonet in place.

Overlap sections to ensure continuous coverage.

Covering the Geonet

For drainage applications, place a layer of soil, gravel, or other materials over the geonet.

Ensure the covering is evenly distributed to prevent damage.

Inspection

Check for any gaps, misalignments, or damages before finalizing the installation.

Geonets are a groundbreaking solution in modern engineering and environmental management. Their applications in drainage, erosion control, landfill management, agriculture, and foundation reinforcement highlight their versatility and importance. With benefits like durability, cost-effectiveness, and environmental friendliness, geonets are indispensable in addressing today’s construction and environmental challenges.

Whether you are a civil engineer, an environmental scientist, or a project manager, understanding the potential of Geonet use in road engineering can help you implement effective and sustainable solutions. By integrating geonets into your projects, you can ensure optimal performance, reduced costs, and a positive environmental impact.

1. What is the lifespan of a geonet?

Geonets are designed to last for decades, with some products offering a lifespan of over 50 years. Their durability depends on the quality of the material, environmental conditions, and proper installation.

2. Can geonets be recycled?

Yes, most geonets are made from recyclable materials like HDPE. Recycling helps reduce waste and promotes environmental sustainability.

3. Are geonets suitable for all types of soil?

Geonets are compatible with most soil types, including sandy, clay, and rocky soils. However, it is essential to consult a professional to determine the best type of geonet for specific soil conditions.

4. How do geonets compare to traditional drainage systems?

Geonets are more efficient and cost-effective than traditional drainage systems. Their lightweight design simplifies installation, and their durability ensures long-term performance without frequent maintenance.