In the fast-paced world of warehousing, efficiency, safety, and precision are paramount. Over the years, material handling equipment has evolved to meet these demands, and one of the most transformative innovations in this area is the hydraulic trolley. With its ability to lift and transport heavy loads with minimal effort, hydraulic trolleys are revolutionizing warehouse operations across industries.

What is a Hydraulic Trolley?

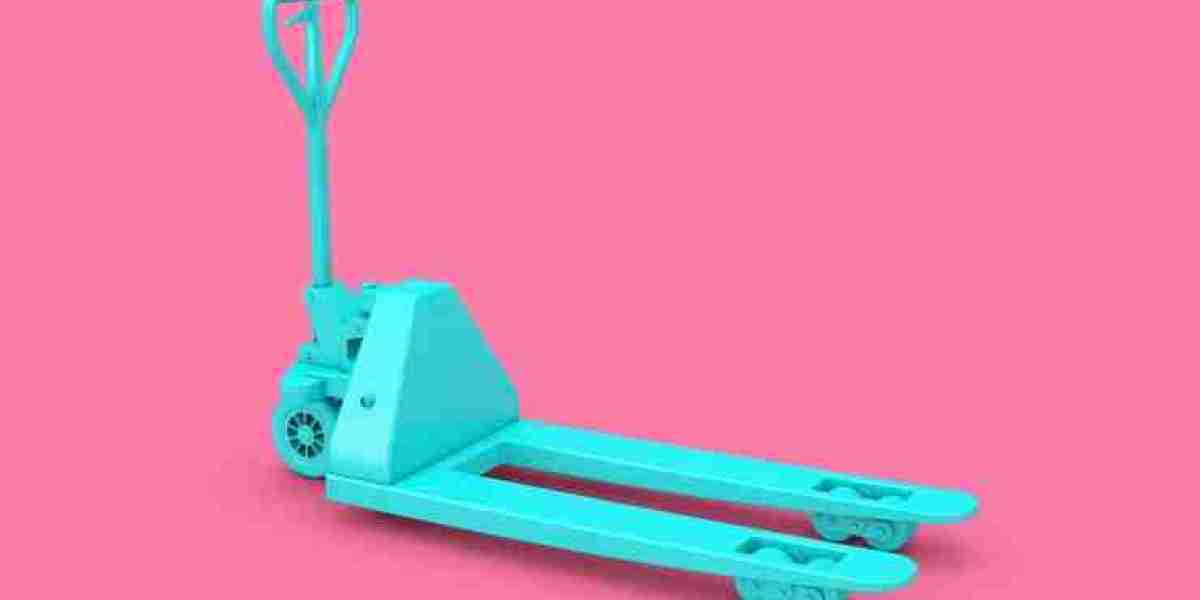

A hydraulic trolley, also known as a hydraulic lift cart or pallet truck, is a piece of equipment designed to move materials within a warehouse or industrial setting. It operates on a hydraulic system that uses fluid pressure to lift heavy loads with ease, providing a smooth and effortless lifting and transportation experience. The trolley is equipped with a pump handle, which the operator uses to engage the hydraulic system, raising the platform to the desired height.

Key Advantages of Hydraulic Trolleys in Warehousing

1. Improved Efficiency

Hydraulic trolleys significantly enhance warehouse efficiency by streamlining the movement of materials. The ability to lift heavy loads reduces the need for manual labor, which not only speeds up the transportation process but also allows workers to focus on other critical tasks. Additionally, hydraulic trolleys can handle a wide range of materials, from boxes to pallets, contributing to smoother operations across the entire warehouse.

2. Increased Safety

Safety is a primary concern in any warehouse, and hydraulic trolleys contribute to a safer working environment. Manual lifting of heavy loads can lead to strain injuries, accidents, and even long-term health problems. Hydraulic trolley minimize these risks by allowing workers to lift and move items without the need for excessive physical effort. This reduces the likelihood of injuries associated with manual handling.

3. Versatility and Adaptability

Hydraulic trolleys are designed to handle various materials and weights, making them highly versatile tools in any warehouse. With adjustable lifting capacities and platform sizes, they can transport everything from small boxes to large, heavy pallets. This adaptability makes hydraulic trolleys ideal for warehouses with diverse inventories, ensuring that the same equipment can be used for multiple tasks.

4. Space Efficiency

In warehouses, maximizing available space is crucial. Hydraulic trolleys help in optimizing space utilization by allowing workers to move materials efficiently between narrow aisles or congested areas. The maneuverability of these trolleys enables easy movement even in cramped spaces, allowing for a more organized and efficient warehouse layout.

5. Cost-Effective Solution

While the initial investment in hydraulic trolleys might seem significant, the long-term savings are substantial. By reducing the need for manual labor, minimizing workplace injuries, and increasing operational speed, warehouses can see a quick return on investment. Furthermore, hydraulic trolleys require minimal maintenance, making them a cost-effective solution for long-term use.

6. Ergonomics

The ergonomic design of hydraulic trolleys ensures that workers can perform tasks without unnecessary strain on their bodies. The ease of operation—whether lifting, lowering, or maneuvering the trolley—helps minimize physical strain and fatigue. This is particularly beneficial in environments where employees must perform repetitive tasks, improving worker productivity and overall job satisfaction.

Types of Hydraulic Trolleys

1. Manual Hydraulic Trolleys

Manual hydraulic trolleys are the most common type found in warehouses. They are operated by a hand pump that activates the hydraulic lifting mechanism. These trolleys are highly effective for low to medium capacity tasks, offering good control and maneuverability for everyday warehouse tasks.

2. Electric Hydraulic Trolleys

Electric hydraulic trolleys combine the advantages of manual models with the added convenience of electrical assistance. These trolleys are equipped with an electric motor that automates the lifting process, reducing the physical effort required from workers. Electric trolleys are ideal for heavier loads or larger warehouses, where greater efficiency is needed.

3. Scissor Lift Trolleys

Scissor lift hydraulic trolleys offer a higher lift range, with a scissor mechanism that provides vertical lifting. These are particularly useful for tasks that require lifting materials to higher shelves or platforms, making them indispensable in warehouses with multi-level storage.

4. Pallet Trucks

Pallet trucks are a form of hydraulic trolley specifically designed to lift and move palletized goods. Available in both manual and electric versions, they are essential for streamlining the transportation of goods on standard-sized pallets, improving productivity in shipping and receiving areas.

Hydraulic Trolleys in Action

Hydraulic trolleys can be found in a variety of sectors, from logistics and e-commerce warehouses to manufacturing plants. Their role in streamlining the flow of materials can be seen in various warehouse activities, such as:

Receiving Goods: Hydraulic trolleys are used to move shipments from the receiving area to the appropriate storage location quickly.

Inventory Management: By enabling workers to move and stack items efficiently, hydraulic trolleys help maintain a streamlined inventory system.

Shipping and Order Fulfillment: During order picking and packing, these trolleys reduce the time spent manually handling products, ensuring faster dispatch times.

Conclusion

Hydraulic trolleys have revolutionized material handling in warehouses, making them indispensable tools for modern warehouses. With their ability to lift and transport heavy loads safely and efficiently, they improve warehouse operations, reduce workplace injuries, and maximize space and productivity. As industries continue to prioritize efficiency and safety, hydraulic trolleys will remain a vital component in the evolution of warehouse material handling systems.