In the electronics manufacturing industry, the process of depaneling is a critical step that involves separating individual printed circuit boards (PCBs) from a larger panel. The efficiency and accuracy of this process can significantly impact the overall quality and reliability of the final product. Traditional depaneling methods often rely on manual labor, which can be time-consuming and prone to errors. To overcome these challenges, high-performance PCB depaneling machines have emerged as a game-changer, offering superior results and transforming the electronics manufacturing landscape.

Advantages of High-Performance PCB Depaneling Machines

High-performance PCB depaneling machines are designed to provide fast, accurate, and reliable separation of PCBs. These machines utilize advanced technologies, such as computer vision and precision cutting tools, to ensure precise and clean separation of the boards. By automating the depaneling process, manufacturers can significantly reduce labor costs and increase productivity. Additionally, the machines can handle a wide range of panel sizes and types, making them an ideal solution for various electronics manufacturing applications.

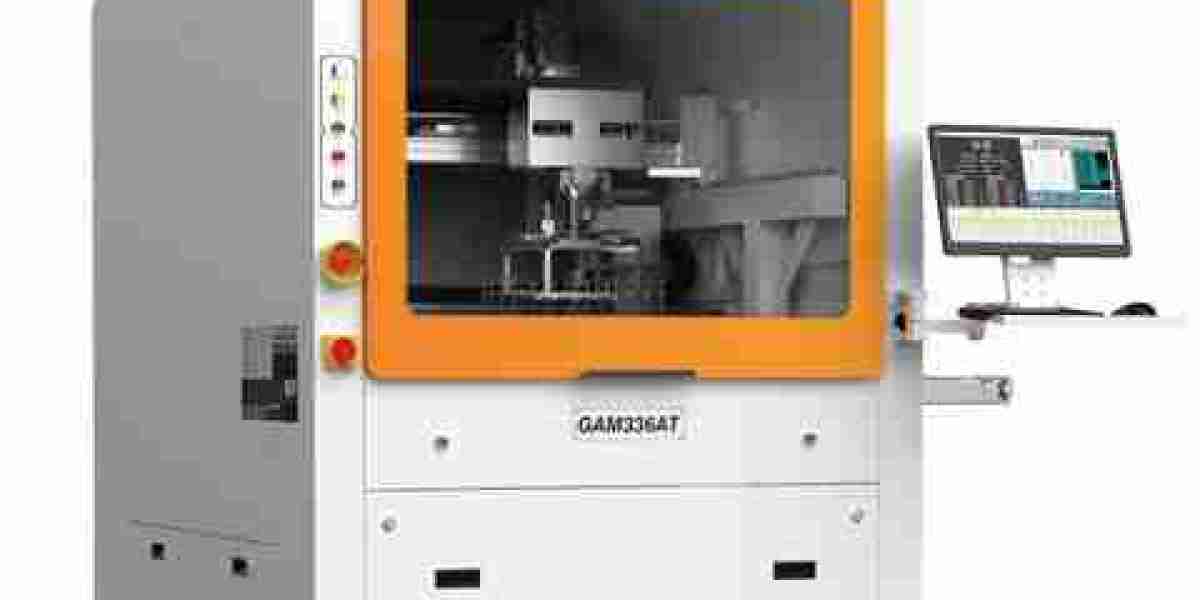

Key Features of High-Performance PCB Depaneling Machines

High-performance PCB depaneling machines are equipped with advanced features that enable superior results. These machines typically feature a high-resolution camera system that captures images of the panel, allowing the machine to identify the PCBs and determine the optimal depaneling path. The machines also utilize precision cutting tools, such as lasers or milling cutters, which ensure clean and precise separation of the PCBs. Furthermore, the machines are designed with a robust and durable construction, ensuring reliable operation and minimal downtime.

Improved Accuracy and Reduced Waste

High-performance PCB Depaneling machines offer improved accuracy and reduced waste compared to traditional depaneling methods. The machines' advanced computer vision system and precision cutting tools ensure that the PCBs are separated accurately and cleanly, reducing the risk of damage and waste. Additionally, the machines can detect and reject defective boards, ensuring that only high-quality PCBs are processed. This level of accuracy and quality control is critical in the electronics manufacturing industry, where even small defects can have significant consequences.

Increased Productivity and Efficiency

High-performance PCB depaneling machines are designed to increase productivity and efficiency in the electronics manufacturing process. By automating the depaneling process, manufacturers can significantly reduce labor costs and increase production rates. The machines can also be easily integrated into existing production lines, allowing manufacturers to upgrade their processes without significant investments in new infrastructure. Additionally, the machines' advanced software provides real-time data on production rates, yield, and defect rates, enabling manufacturers to optimize their processes and improve overall efficiency.

Industry Applications and Future Prospects

High-performance PCB depaneling machines have far-reaching applications in various industries, including consumer electronics, automotive, aerospace, and medical devices. As the demand for electronics continues to rise, the adoption of these machines is expected to increase, driving growth and innovation in the industry. Furthermore, the integration of emerging technologies, such as artificial intelligence and the Internet of Things (IoT), is expected to further enhance the capabilities of high-performance PCB depaneling machines, enabling even greater efficiency and precision.

Conclusion

In conclusion, high-performance PCB depaneling machines have revolutionized the electronics manufacturing industry, offering superior results and transforming the depaneling process. These machines have improved accuracy, reduced waste, and increased productivity, making them an essential component of modern electronics manufacturing. As the industry continues to evolve, the adoption of high-performance PCB depaneling machines is expected to increase, driving growth, innovation, and competitiveness. With their advanced features, benefits, and industry applications, high-performance PCB depaneling machines are poised to play a vital role in shaping the future of electronics manufacturing.