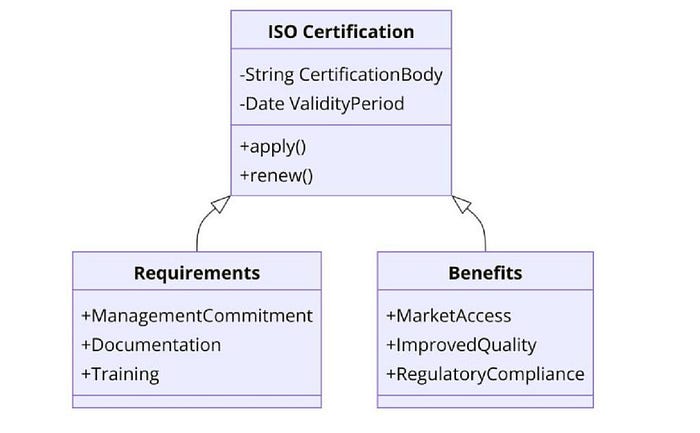

In the safety equipment and supplies manufacturing sector, adhering to globally recognized standards is not a recommendation — it’s a necessity. With increasing regulatory demands and market expectations, ISO certifications ensure that manufacturers meet rigorous safety and operational efficiency benchmarks.

The International Organization for Standardization (ISO) sets globally recognized benchmarks that ensure product safety, environmental sustainability, and operational excellence. For manufacturers of safety equipment and supplies, these certifications signify adherence to high-quality processes and commitment to protecting lives.

ISO standards address critical aspects of the manufacturing process, from product quality and workplace safety to environmental management. Compliance demonstrates reliability and fosters trust among clients, partners, and end-users. In today’s competitive landscape, an ISO-certified company stands as a beacon of quality and dependability.

Send your inquiries and requirements to support@pacificcert.com for prompt assistance with ISO certification processes.

Applicable ISO Standards for Safety Equipment and Supplies Manufacturing

ISO 9001: Quality Management Systems: ISO 9001 establishes a framework for quality management systems (QMS). It ensures consistent product quality, efficient processes, and customer satisfaction. For safety equipment manufacturers, it ensures products meet stringent safety and performance criteria.

ISO 45001: Occupational Health and Safety Management: ISO 45001 focuses on occupational health and safety (OHS). It is pivotal for manufacturing environments where employee safety is paramount. This standard helps organizations mitigate workplace hazards and create safer working conditions.

ISO 14001: Environmental Management Systems: Given the environmental impact of manufacturing activities, ISO 14001 addresses sustainable practices. This standard helps manufacturers minimize environmental footprints through effective resource management and pollution control.

ISO 13485: Medical Devices: For manufacturers of medical safety equipment, ISO 13485 is critical. It outlines the requirements for a QMS tailored to the medical devices industry, ensuring compliance with regulatory standards for medical-grade products.

ISO 50001: Energy Management Systems: Energy-intensive manufacturing processes benefit from ISO 50001, which focuses on optimizing energy usage. Implementing this standard can lead to reduced energy costs and a lower environmental impact.

ISO 22301: Business Continuity Management: Safety equipment manufacturers must ensure uninterrupted operations during emergencies. ISO 22301 helps organizations prepare for, respond to, and recover from disruptive incidents.

ISO 31000: Risk Management: Risk management is vital for manufacturing high-stakes safety equipment. ISO 31000 provides guidelines for identifying, assessing, and managing risks effectively.

Click here to find out more applicable standards to your industry

Pacific Certifications specializes in providing ISO certification services tailored to safety equipment and supplies manufacturing. Our experienced auditors ensure that your processes align with the relevant ISO standards, issuing certifications upon successful compliance. As a trusted certification body, we empower manufacturers to achieve excellence and build credibility in global markets.

Why Choose Pacific Certifications?

- Expertise in safety equipment manufacturing certifications.

- Accredited certification processes.

- Timely and professional audit services.

To discuss your certification needs, contact us at support@pacificcert.com.

Speak to our certification specialists by calling +91–8595603096 for personalized guidance.

Read More: ISO Certifications for Safety Equipment and Supplies Manufacturing