The Propylparaben Production Cost plays a crucial role in determining the profitability and pricing structure of businesses involved in the production of this widely used preservative. Propylparaben, a synthetic compound commonly used in the cosmetics, pharmaceutical, and food industries, is valued for its ability to prevent the growth of harmful bacteria and fungi. As demand for propylparaben continues to rise, particularly with the growing need for preservatives in personal care products and pharmaceuticals, understanding the cost structure of its production is essential for manufacturers and businesses.

Request a Free Sample – https://www.procurementresource.com/production-cost-report-store/propylparaben/request-sample

In this article, we will delve into the various factors influencing Propylparaben Production Cost, including cost models, pre-feasibility studies, labor charges, utility costs, logistics, supply chain factors, and current industrial trends. Furthermore, we will explore how these factors impact the overall cost-effectiveness of production and provide insights into how businesses can optimise their production process for maximum profitability.

Understanding Propylparaben and Its Production Process

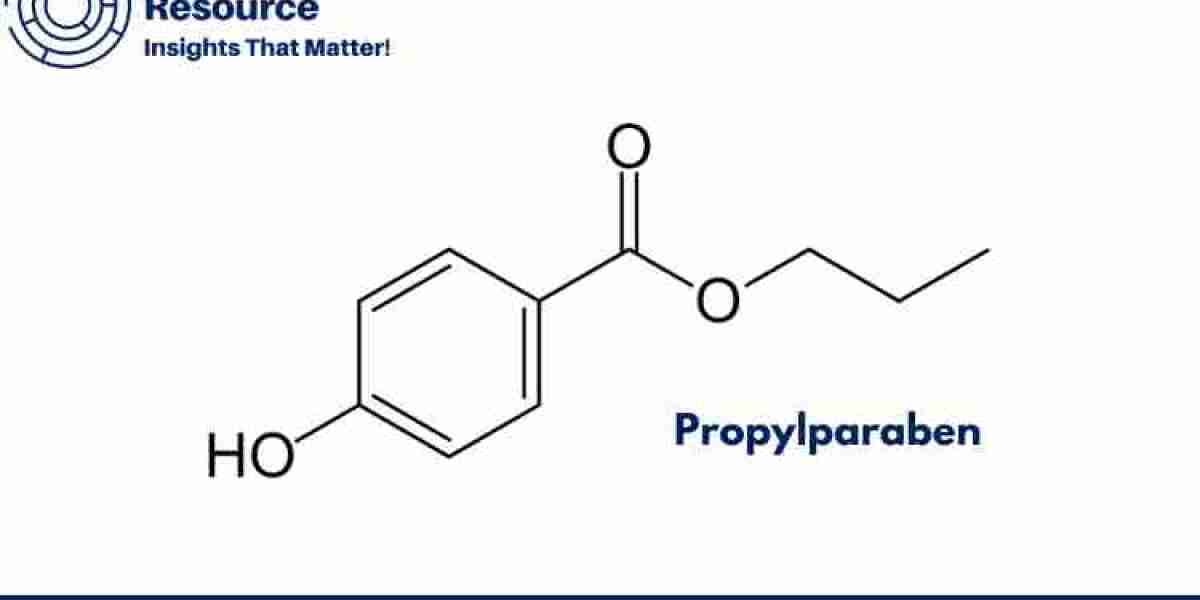

Propylparaben, also known as n-propyl 4-hydroxybenzoate, is an ester of p-hydroxybenzoic acid. It is primarily used as a preservative in cosmetic and personal care products, pharmaceuticals, and food items due to its antimicrobial properties. Propylparaben effectively inhibits the growth of a wide range of microorganisms, which helps in extending the shelf life of products without compromising their quality.

The production process for propylparaben involves the esterification of p-hydroxybenzoic acid with n-propyl alcohol, followed by purification and formulation processes to achieve the desired product specifications. The overall production cost is influenced by several factors, ranging from raw material prices to the efficiency of the manufacturing process.

Cost Model and Pre-feasibility Study

A well-defined cost model is essential for businesses looking to enter or expand their operations in propylparaben production. The Propylparaben Production Cost can be broken down into several key components, each of which contributes to the final price of the product. Some of the primary cost factors include:

Raw Materials: The most significant costs involved in propylparaben production are the raw materials—primarily p-hydroxybenzoic acid and n-propyl alcohol. These materials must be sourced from suppliers, and their prices can fluctuate based on market conditions, availability, and quality.

Labor Charges: Labor costs include wages for skilled workers, machine operators, engineers, and supervisors. These charges can vary depending on the location of the manufacturing plant, the level of automation, and the efficiency of the workforce.

Utilities: Manufacturing propylparaben requires energy, water, and other essential utilities. The consumption of electricity, steam, and water for the esterification process contributes significantly to the production cost. Utility costs can vary based on local infrastructure and energy prices, which may impact overall profitability.

Production Yield and Efficiency: The yield from the esterification reaction and the efficiency of the purification processes directly affect the overall production cost. High yields and efficient processes help reduce waste and minimise operational expenses, thus lowering the production cost per unit of propylparaben.

Overhead Costs: These include costs associated with plant maintenance, administration, marketing, research and development, quality control, and regulatory compliance. Ensuring product quality and meeting regulatory standards are essential to maintaining business operations, but these overheads must be carefully managed to optimise profitability.

A pre-feasibility study for propylparaben production can help businesses assess whether the investment in manufacturing facilities will provide a sustainable return on investment (ROI). This analysis typically evaluates factors such as market demand, capital expenditure (CapEx), operating expenditure (OpEx), expected production volumes, and the time frame for reaching profitability.

Industrial Trends Affecting Propylparaben Production

In recent years, several industrial trends have impacted the Propylparaben Production Cost. These trends include:

Demand for Natural and Organic Preservatives: There is a growing trend toward natural and organic preservatives in cosmetics, pharmaceuticals, and food products due to increasing consumer awareness and demand for safer, non-toxic ingredients. This trend may drive research into alternative preservatives, potentially influencing the cost of propylparaben production.

Regulatory Changes: Increasing regulations around the use of preservatives in food and personal care products are pushing manufacturers to adapt their production processes. For instance, the European Union has stricter guidelines regarding the use of parabens in cosmetics. Such regulations can affect the demand for propylparaben and may impact production costs if businesses need to invest in compliance measures.

Sustainability and Eco-friendly Production: As environmental concerns grow, many manufacturers are investing in greener production processes to reduce their carbon footprint. This includes implementing energy-efficient equipment, recycling waste, and sourcing sustainable raw materials. While these initiatives can initially increase costs, they may offer long-term savings and appeal to environmentally conscious consumers.

Technological Advancements: Advancements in production technologies, such as improved catalysts for the esterification process and more efficient purification methods, can lower operational costs and improve production yields. Automation and process optimisation are key trends in many manufacturing industries, including propylparaben production.

Logistics and Supply Chain Considerations

Logistics and supply chain management play an important role in controlling the Propylparaben Production Cost. Effective supply chain management ensures that raw materials are delivered on time, production processes run smoothly, and finished products are distributed efficiently to customers. Here are some important factors to consider:

Raw Material Sourcing: Securing reliable sources of high-quality p-hydroxybenzoic acid and n-propyl alcohol is essential for maintaining a steady production flow. Disruptions in the supply of these materials can lead to increased costs, delays, and potential stockouts. Procurement teams must ensure that they have backup suppliers in place and consider purchasing materials in bulk to secure better prices.

Transportation and Distribution: Transporting raw materials and finished products can add significant costs to production. Optimising transportation routes, negotiating favorable contracts with logistics providers, and consolidating shipments are strategies that can help reduce transportation costs.

Inventory Management: Managing inventory effectively is crucial for reducing holding costs and ensuring that production meets demand. Businesses must carefully balance their inventory levels to avoid stockouts or excess stock, both of which can impact the production cost and overall efficiency.

Request for the Real-Time Prices

If you're interested in obtaining the latest Propylparaben Production Cost and market insights, you can access real-time data from industry-leading sources.

For more detailed information or to request Free Sample - https://www.procurementresource.com/production-cost-report-store/propylparaben/request-sample

Procurement Resource: Key Considerations for Sourcing Raw Materials

When setting up or expanding a propylparaben production plant, understanding the procurement process is vital for cost control and supply chain efficiency. Engaging reliable suppliers for key raw materials like p-hydroxybenzoic acid and n-propyl alcohol, negotiating long-term contracts, and using strategic sourcing methods can help mitigate price fluctuations and secure consistent supply.

Procurement professionals should also consider diversifying suppliers, exploring local sources to reduce logistics costs, and investing in quality control measures to ensure raw material quality meets production standards.

By optimising procurement strategies, businesses can effectively manage production costs and ensure that their operations remain profitable and sustainable in the long term.

Contact Us

Company Name: Procurement Resource

Contact Person: Amanda Williams

Email: sales@procurementresource.com

Toll-Free Numbers:

USA: 1 307 363 1045

UK: 44 7537171117

Asia-Pacific (APAC): 91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA