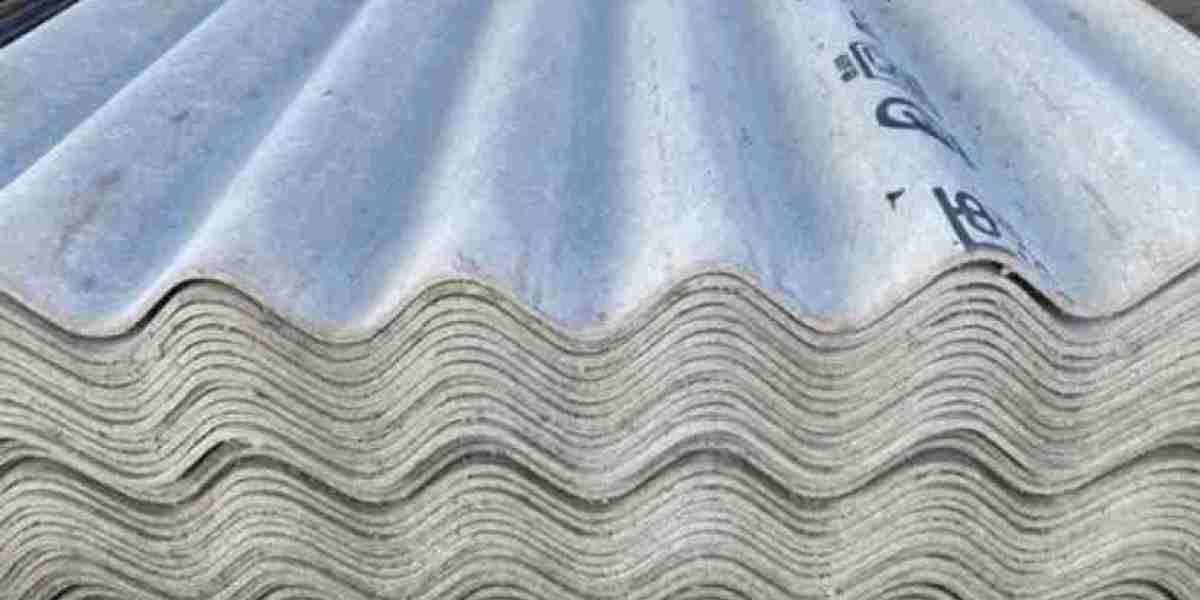

Asbestos ridges, commonly used in roofing and construction, are durable and cost-effective materials that provide reliable protection against weather elements. These ridges are essential for sealing and reinforcing roofing structures, especially in industrial and agricultural buildings. Despite regulatory restrictions in certain regions, the demand for asbestos ridges persists in many markets due to their affordability and effectiveness. Establishing an asbestos ridges manufacturing plant offers an opportunity to serve these markets while adhering to strict safety and compliance standards.

Market Overview

The asbestos ridges market is sustained by demand from industries and regions where cost-effective construction materials are essential. These ridges are widely used in rural and industrial areas for roofing solutions, thanks to their durability and ability to withstand harsh weather conditions. While some countries have imposed restrictions on asbestos usage, others continue to rely on it due to its economic advantages and availability. Innovations in manufacturing techniques have also improved the safety and quality of asbestos-based products, expanding their appeal in applicable markets.

Get a Free Sample Report with Table of Contents@ https://www.expertmarketresearch.com/prefeasibility-reports/asbestos-ridges-manufacturing-plant-project-report/requestsample

Manufacturing Process

The production of asbestos ridges involves several precise steps to ensure quality, safety, and adherence to regulatory standards:

Raw Material Procurement:

Chrysotile asbestos fibres, cement, and other additives are sourced from reliable suppliers to ensure consistency in quality.Mixing:

The raw materials are blended in specific proportions using automated mixing equipment to form a homogenous mixture.Moulding:

The mixture is shaped into ridges using moulding machines, ensuring uniformity and structural integrity.Curing:

The moulded ridges are cured under controlled conditions to enhance their strength and durability.Cutting and Finishing:

The cured ridges are trimmed to the required dimensions and inspected for defects to ensure they meet quality standards.Packaging:

The finished products are packed in bundles or crates for easy transportation and storage.

Key Considerations for Setting Up the Plant

- Location: Choose a site with access to raw material suppliers and close to key markets to minimise transportation costs.

- Infrastructure: Invest in advanced moulding, curing, and quality control equipment to optimise production efficiency.

- Compliance: Adhere to local regulations and safety standards for asbestos handling and production.

- Workforce Training: Train employees on the safe handling of asbestos and proper use of manufacturing equipment to ensure workplace safety.

Benefits of Asbestos Ridges Manufacturing

- Cost-Effectiveness: Affordable raw materials and production methods make asbestos ridges a budget-friendly option for consumers.

- Durability: Resistant to weathering and wear, ensuring long-lasting performance in construction applications.

- High Demand in Specific Markets: Essential for rural and industrial construction in regions where asbestos usage is permitted.

- Ease of Production: Relatively straightforward manufacturing process with established techniques.

Target Audience

The primary consumers of asbestos ridges include:

- Construction Companies: Firms specialising in industrial, agricultural, and rural infrastructure projects.

- Distributors: Wholesalers supplying roofing materials to retail and commercial markets.

- Rural Markets: Communities and businesses requiring affordable and durable roofing solutions.

- Export Markets: Regions with high demand for cost-effective construction materials.

Challenges and Solutions

- Regulatory Restrictions: Compliance with safety regulations and exploring alternative fibres where necessary can ensure market access.

- Health Concerns: Investing in advanced dust control systems and protective measures minimises risks associated with asbestos handling.

- Market Competition: Differentiating products through superior quality, efficient production, and reliable delivery strengthens competitiveness.

Marketing Strategies

To establish a strong presence in the asbestos ridges market, manufacturers can adopt the following strategies:

- B2B Partnerships: Collaborate with construction firms and distributors to expand market reach.

- Educational Campaigns: Promote the safety measures implemented in manufacturing to build trust among consumers and regulators.

- Digital Marketing: Leverage online platforms to showcase the benefits and applications of asbestos ridges in construction.

- Sustainability Initiatives: Highlight environmentally conscious practices in manufacturing and explore alternative materials for future products.

Sustainability in Manufacturing

Sustainability is an important consideration in asbestos ridges production. By adopting energy-efficient manufacturing processes, minimising waste, and using advanced dust control systems, manufacturers can reduce their environmental footprint. Exploring alternative, eco-friendly materials for ridge production may also open new market opportunities while addressing regulatory concerns.

Future Outlook

The demand for asbestos ridges is expected to persist in markets that prioritise cost-effective and durable construction materials. Innovations in manufacturing technologies and adherence to safety and compliance standards will play a critical role in sustaining the market. By focusing on quality, safety, and customer engagement, manufacturers can secure a competitive edge in this niche yet significant industry. Establishing an asbestos ridges manufacturing plant offers a viable opportunity to cater to the construction needs of developing and industrial regions.