In the construction and steel fabrication industries, the estimation and takeoff processes are essential for ensuring the accurate planning and budgeting of projects. These processes help identify material requirements, labor costs, and overall project expenses, which are key to achieving project success. When it comes to steel projects, the precision of steel estimation and takeoff services can significantly impact the final cost, timeline, and quality of the work. Steel estimation and takeoff is a methodical process that helps construction firms, engineers, and contractors prepare for the scope of work, and it involves a detailed breakdown of steel materials, quantities, and dimensions.

What is Steel Estimation & Takeoff?

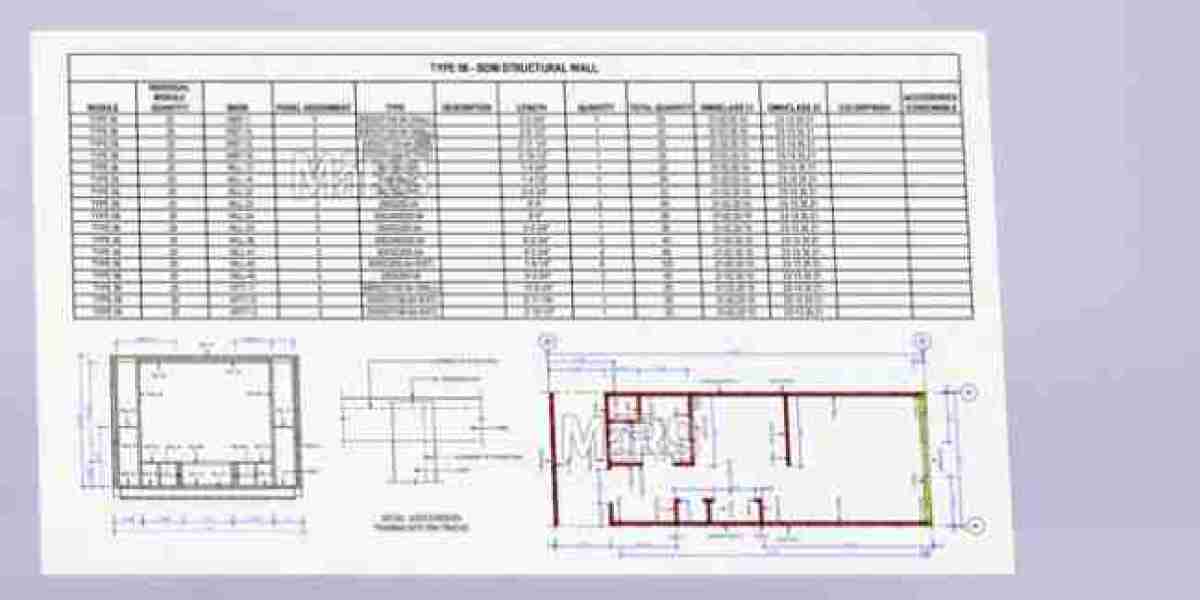

Steel estimation and takeoff is a systematic process in which construction professionals calculate the quantities of steel required for a particular project, taking into account the specific design and structural needs. These calculations are critical for the preparation of accurate budgets and the procurement of materials, enabling contractors to streamline procurement and reduce costs. Steel takeoff involves reviewing project blueprints, plans, or digital models and extracting detailed information regarding the steel components. This information includes everything from steel beams, columns, and plates to bolts, rivets, and welding materials.

During the Steel Estimation & Takeoff process, experts consider various factors, such as the type of steel, project specifications, local material prices, and labor costs. The process is designed to avoid underestimation or overestimation, ensuring that the project is neither over-budget nor under-resourced. Accurate Steel Estimation & Takeoff also helps prevent material shortages or excess stock, both of which can disrupt the construction process. In addition to estimating material quantities, the takeoff includes the calculation of cutting lists and fabrication schedules, which are essential for contractors and fabricators to plan their work.

Why is Steel Estimation & Takeoff Important?

Steel estimation and takeoff serve several purposes in a construction project, all of which contribute to its overall success. First and foremost, accurate steel estimation and takeoff ensure that the project is financially viable. By calculating the right quantities of steel and other related materials, construction professionals can provide an accurate budget to clients, enabling them to secure financing and make informed decisions.

Moreover, steel estimation and takeoff are crucial for optimizing resource management. When project managers have precise estimates of the steel required, they can plan the procurement and scheduling of materials with greater efficiency, helping prevent delays caused by material shortages or excess inventory. Additionally, a well-executed takeoff can facilitate better coordination between various contractors and subcontractors, as it provides them with a clear understanding of the materials they will need to source and work with.

The accuracy of steel estimation and takeoff also plays a key role in maintaining project timelines. A detailed takeoff ensures that the right materials are delivered at the right time, reducing the risk of delays caused by material shortages. This is especially important in large-scale projects, where steel components often have long lead times. Furthermore, steel estimation and takeoff provide contractors with the necessary information to allocate labor resources appropriately, ensuring that skilled workers are available when needed for fabrication and installation.

Key Components of Steel Estimation & Takeoff

Project Drawings and Specifications: The foundation of steel estimation and takeoff is the set of project drawings and specifications. These documents provide detailed information about the design and dimensions of the steel structure, including beams, columns, and other components. Estimators must carefully analyze these drawings to identify the quantity and type of steel required for the project. In addition, the project specifications provide essential details about the material grade, finish, and any specific treatment that the steel may require.

Steel Material Quantities: Once the drawings and specifications are reviewed, the next step is to calculate the quantities of steel needed. This involves measuring the length, width, and thickness of each steel component and determining how much material will be required to fabricate it. In some cases, estimators may use specialized software to generate precise quantities based on the project’s digital models or CAD drawings.

Cutting Lists and Fabrication Schedules: Steel takeoff also includes the preparation of cutting lists and fabrication schedules. A cutting list specifies how each steel piece should be cut and shaped to meet the project’s requirements. It includes details like the lengths of beams, angles, and plates that need to be cut. Fabrication schedules, on the other hand, outline when and how each piece of steel will be fabricated, allowing for better coordination between the fabrication shop and the construction site.

Labor and Overhead Costs: In addition to estimating the quantity of steel, steel estimation also involves calculating the labor costs associated with fabrication, welding, and installation. Estimators consider the complexity of the project, the number of workers needed, and the time required to complete the tasks. Overhead costs, including transportation, equipment rental, and insurance, are also factored into the estimation to ensure that the final budget is comprehensive.

Contingency and Waste Factors: No project is without its challenges, and steel estimation takes into account the possibility of waste and unforeseen circumstances. Estimators include contingency factors to cover material waste, changes in the design, or potential errors in fabrication. By factoring in these elements, construction professionals can ensure that the project remains on budget, even if unexpected issues arise.

The Role of Technology in Steel Estimation & Takeoff

Advancements in technology have revolutionized the way steel estimation and takeoff are performed. Traditionally, estimators would rely on manual calculations and physical takeoff sheets, but today, digital tools and software have streamlined the process. Using advanced software, estimators can input project data and generate accurate material takeoffs and cost estimates with just a few clicks.

Software solutions for steel estimation often include features like 3D modeling, automated takeoff generation, and integration with other project management tools. These tools allow estimators to visualize the project in a 3D environment, making it easier to identify potential issues or discrepancies early in the process. Additionally, digital takeoff tools can automatically generate cutting lists and fabrication schedules, reducing the risk of human error and speeding up the overall estimation process.

Challenges in Steel Estimation & Takeoff

Despite the advances in technology, steel estimation and takeoff remain complex tasks that require expertise and attention to detail. One of the main challenges in steel estimation is dealing with incomplete or inaccurate project drawings. If the design changes during the construction process, it can disrupt the estimation and takeoff process, leading to delays and cost overruns. Additionally, variations in local material prices, labor rates, and other external factors can complicate the budgeting process.

Another challenge is managing the vast amount of data involved in steel estimation and takeoff. Large-scale projects often involve hundreds or even thousands of steel components, and manually tracking these components can be time-consuming and error-prone. To overcome this challenge, many construction professionals rely on software solutions that can manage and analyze large datasets, ensuring that all materials and quantities are accounted for.

Conclusion

Steel estimation and takeoff are essential components of any construction project involving steel fabrication. By accurately calculating the quantities and costs of steel materials, construction professionals can avoid costly mistakes, optimize resource management, and ensure timely project completion. With the help of advanced software tools and the expertise of skilled estimators, steel estimation and takeoff services can significantly contribute to the overall success of a project. Whether working on a small-scale building or a large infrastructure project, accurate steel estimation and takeoff provide the foundation for a well-executed and cost-effective construction process.