Global Honeycomb Sandwich Material Industry: Key Statistics and Insights in 2025-2033

Summary:

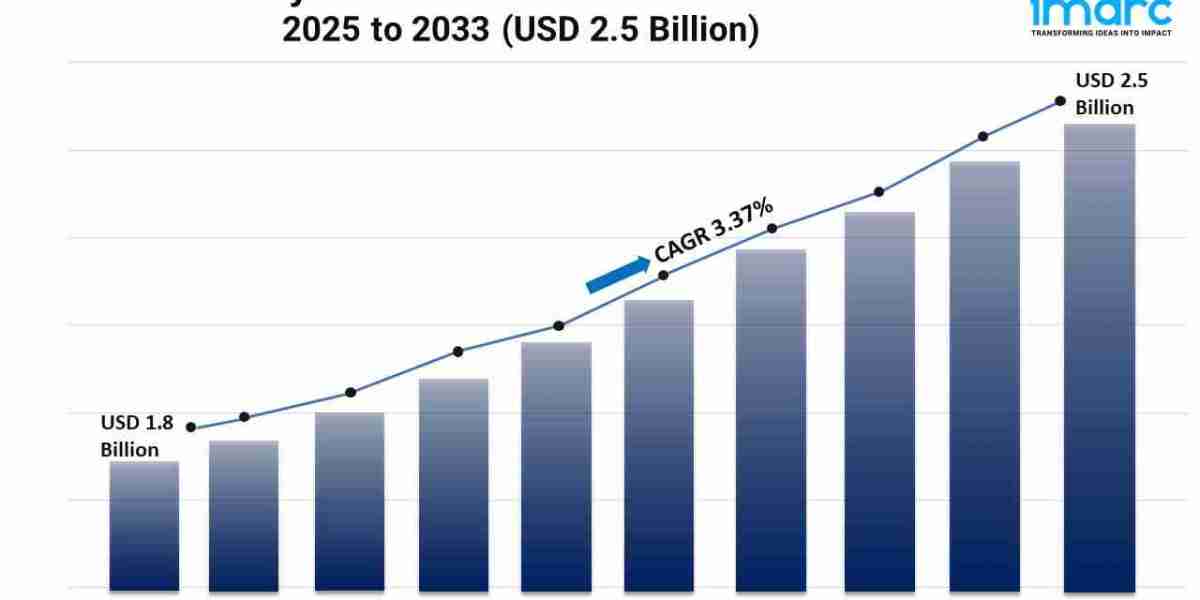

- The global honeycomb sandwich material market size reached USD 1.8 Billion in 2024.

- The market is expected to reach USD 2.5 Billion by 2033, exhibiting a growth rate (CAGR) of 3.37% during 2025-2033

- North America leads the market, accounting for the largest honeycomb sandwich material market share.

- Aluminum holds the majority of the market share in the material type segment due to its ability to offer resistance to corrosion and high temperatures.

- Expansion exhibits a clear dominance in the honeycomb sandwich material industry.

- Aerospace remains a dominant segment in the market, as it requires high-strength and durable components that can withstand extreme environmental conditions.

- The rising utilization in the construction sector is a primary driver of the honeycomb sandwich material market.

- Technological advancements in material production methods are reshaping the honeycomb sandwich material market.

Industry Trends and Drivers:

- Thriving automotive industry:

The honeycomb sandwich material market creates a new horizon, where all automotive sectors are concerned competitive in making the vehicle weightless by following strict emission norms to enhance the overall fuel efficiency. Honeycomb augment body panels, chassis, and interior parts, wherein adding sheer performance of vehicles. Electric vehicles are also another weight-influencing factor since it optimizes battery range and energy use with lightweight materials. Such a transition will boost future demands for honeycomb materials as that would inspire them to be essentials of automotive innovation and sustainability.

- Rising use in construction:

Honeycomb sandwich panels are employed by the construction industry for their strength-to-weight ratio and their easy installation facilities. Hence, facades, roofing, and partitions are introduced in the building, which minimizes the structural load and simplifies the construction processes. In addition to these uses, honeycomb panels allow better thermal and acoustic insulation, thus improving efficiencies in energy consumption with eco-friendly designs. Their shape and finish textural versatility are attractive for modern architectural aesthetics and flexible design possibilities. Their durability and versatility have also made them popular among sustainable projects, thus enhancing global market growth.

- Technological advancements in material production:

Innovative material technologies are permitting the creation of devices and products that are more efficient, stronger, and even more versatile. Advanced composite materials made of carbon-fibre reinforcement and advanced polymer composites are improving honeycomb structures by making strength-to-weight ratios even better and improving impact absorption or resistance to thermal stability. Besides, improving the cost-effectiveness of production, such as automated fabrication or 3D printing, is achieving finer-tuning of production custom solutions that can meet individual performance specifications. Furthermore, enhanced production methods speed up honeycomb materials' scaling for larger applications. Thus they increase the applications of honeycomb materials and lower their prices.

Request for a sample copy of this report: https://www.imarcgroup.com/honeycomb-sandwich-material-market/requestsample

Honeycomb Sandwich Material Market Report Segmentation:

Breakup By Material Type:

- Aluminum

- Steel

- Composites

- Titanium

- Inconel

- Others

Aluminum represents the largest segment due to its excellent strength-to-weight ratio and widespread use in aerospace and automotive applications.

Breakup By Technology:

- Expansion

- Corrugation

- Molding

- Extrusion

- Others

Expansion accounts for the majority of the market share as it allows for the efficient production of lightweight and high-strength honeycomb cores.

Breakup By Application:

- Aerospace

- Automotive

- Marine

- Locomotive

- Construction

- Others

Aerospace exhibits a clear dominance in the market because of the rising demand for lightweight materials in this industry to enhance fuel efficiency and structural integrity.

Breakup By Region:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

North America enjoys the leading position in the honeycomb sandwich material market owing to its established aerospace and defense industries and significant investments in advanced manufacturing technologies.

Top Honeycomb Sandwich Material Market Leaders:

The honeycomb sandwich material market research report outlines a detailed analysis of the competitive landscape, offering in-depth profiles of major companies. Some of the key players in the market are:

- 3M Company

- S. Innovation

- Corex Honeycomb (Encocam Ltd)

- EconCore N.V.

- General Veneer Manufacturing Co.

- Hexcel Corporation

- Honylite Private Limited

- Pacific Panels Inc.

- Samia Canada Inc.

- Schütz GmbH & Co. KGaA

- The Gill Corporation.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145