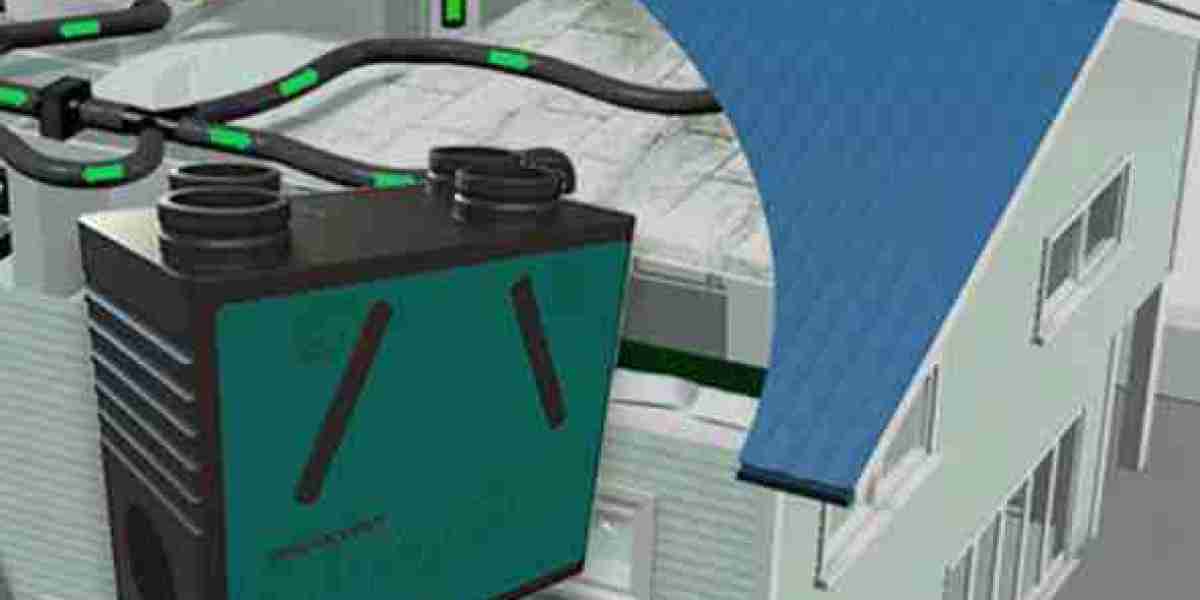

Heat-recovery exchangers are designed to capture and reuse heat from industrial processes that would typically be lost. By transferring heat from exhaust streams to incoming air or fluid streams, these systems enhance the overall energy efficiency of industrial operations. The process involves a heat exchanger, which transfers thermal energy between two mediums without mixing them. This technology reduces the reliance on external energy sources by using the heat already present within the system. As a result, industries can achieve significant energy savings and reduce their environmental impact. Implementing heat recovery exchangers can lead to more sustainable and cost-effective industrial practices.

Achieving Cost Savings with Heat-Recovery Exchangers

Heat-recovery exchangers offer substantial financial benefits for industrial operations. By capturing and reusing waste heat, these systems reduce the need for additional energy input, decreasing overall energy consumption. Lower energy use translates directly into reduced utility expenses, which can represent a significant portion of an industrial facility’s operating costs. Additionally, the decreased demand for external energy sources means that industries are less vulnerable to fluctuations in energy prices.

Over time, the cumulative cost savings from reduced energy bills can be substantial, making the initial investment in heat-recovery exchangers highly worthwhile. Properly implemented and maintained, these systems deliver financial savings throughout their operational lifespan.

Environmental Advantages of Air Recovery Ventilation Systems

Air-recovery ventilation systems significantly reduce an industry’s environmental footprint by efficiently reusing heat energy that would otherwise be wasted. These systems lower the demand for external energy sources, often involving burning fossil fuels, thereby decreasing the overall carbon emissions. Reducing greenhouse gases directly aligns with global initiatives to mitigate climate change. In addition, by enhancing energy efficiency, air-recovery ventilation systems help to preserve natural resources, fostering a more sustainable approach to industrial operations.

Improved air quality is another benefit, as these systems effectively manage indoor pollutants and maintain a healthier work environment. This dual advantage of reducing external emissions and improving internal air quality underscores the environmental significance of adopting air recovery ventilation systems. Industries reduce energy consumption and contribute to broader environmental conservation efforts by integrating such systems. This positions air -recovery ventilation systems as vital in pursuing greener and more responsible industrial practices.

Choosing the Best Heat Recovery Ventilation System

When evaluating a heat recovery ventilation system, it is crucial to consider several factors to ensure it meets the facility’s specific requirements. Firstly, assessing the system’s energy efficiency rating is vital, as higher efficiency systems offer greater energy savings. The capacity of the system to manage the facility’s air volume and heat load must also be examined to ensure it can meet operational demands.

Another key consideration is the ease of integration with the existing infrastructure; a system that seamlessly fits into current setups minimises disruption and installation costs. Additionally, it is essential to look at performance metrics such as heat transfer efficiency and air exchange rates. These metrics provide insight into the system’s effectiveness in recovering heat and maintaining air quality.

Noise levels and the system’s operational complexity should also be evaluated to ensure it aligns with the facility’s requirements. The most best heat recovery ventilation system can be identified by carefully considering these factors, maximising energy efficiency and environmental benefits.

Maintenance and Durability of Heat Recovery Systems

Heat recovery systems are crucial in optimising energy use and contributing to environmental sustainability. Their performance and lifespan greatly depend on regular maintenance and care.

Importance of Routine Maintenance

Regular maintenance is essential for the longevity of heat recovery systems. Frequent inspections are necessary to spot wear or potential problems early, preventing them from becoming larger issues. Cleaning integral components, such as filters and heat exchangers, is vital to keep the system efficient and avoid blockages or harm. Ensuring all moving parts are adequately lubricated and replacing worn-out components swiftly can further extend the system’s operational life.

Monitoring Performance Metrics

Tracking system performance is important for maintaining energy efficiency. Timely adjustments based on performance data can prevent inefficiencies. Establishing a detailed maintenance plan that includes periodic servicing by skilled technicians guarantees the system remains reliable and functions effectively. Keeping comprehensive maintenance logs helps assess the system’s condition and identify persistent problems that may require attention.

Investing in Quality and Following Guidelines

Using high-quality components and following manufacturer maintenance guidelines can improve the system’s durability. Appropriate ventilation and environmental management within the facility are also important for the system’s optimal performance. Through consistent and thorough maintenance practices, industries can ensure that their heat recovery systems provide ongoing energy savings and environmental benefits.

Identifying the Best Heat Recovery Ventilator

Selecting the optimal heat recovery ventilator necessitates thoroughly evaluating the facility’s requirements and environmental conditions. The size and layout of the building play a crucial role in determining the appropriate ventilator capacity. Climate considerations are also essential, as varying temperatures and humidity levels can impact the ventilator’s performance.

Energy efficiency is key in this selection process; ventilators with high-efficiency ratings provide better energy recovery and cost savings. Compatibility with the existing best heat recovery ventilator ensures seamless integration, minimising installation disruptions. Moreover, examining the ventilator’s noise levels is essential to ensure it meets the facility’s comfort standards.

Durability and ease of maintenance are additional considerations, as these factors influence long-term operational efficiency and maintenance costs. Ventilators with advanced filtration systems can also enhance indoor air quality by removing pollutants and allergens.

The choice of heat recovery ventilator should also be guided by its ability to meet regulatory standards and certifications, which can assure performance and reliability. The most suitable heat recovery ventilator can be selected by carefully evaluating these parameters, offering enhanced energy efficiency and improved indoor air quality.

Exploring Passive Ventilation with Heat Recovery

Passive ventilation with heat-recovery leverages natural airflow to regulate indoor environments while simultaneously capturing and reusing heat. This method uses architectural features such as vents, louvres, and strategically placed openings to promote air circulation driven by natural forces like wind and thermal buoyancy. When integrated with heat recovery systems, the incoming fresh air can be pre-warmed by the outgoing exhaust air without mechanical intervention. This synergy not only conserves energy but also enhances indoor air quality.

Passive ventilation with heat recovery are particularly effective in buildings with sustainable architecture, where the building’s orientation and design facilitate optimal air movement. The combination of passive ventilation and heat recovery is especially beneficial in temperate climates, where external temperatures are conducive to natural airflow. Implementing such systems can significantly reduce the reliance on mechanical heating and cooling, leading to lower energy consumption and operational costs.

Additionally, by minimising the need for mechanical systems, maintenance requirements are reduced, further contributing to cost savings. This approach underscores the potential for combining traditional architectural principles with modern energy recovery technology to achieve greater sustainability in building management.

Economic Effects of Adopting Heat-Recovery Exchangers

The economic impact of adopting heat-recovery exchangers in industrial settings is notably significant. These systems enable substantial reductions in energy expenditure by optimising waste heat, allowing industries to redirect financial resources to other critical areas. The initial capital outlay for installing heat-recovery exchangers is often offset by the ongoing savings on energy bills, typically leading to a favourable return on investment within a relatively short period.

Moreover, the enhanced energy efficiency achieved through these systems can qualify facilities for various governmental incentives and rebates, further improving the economic viability of the investment. Beyond direct cost savings, the increased energy efficiency can also improve operational stability by mitigating the risks associated with energy price volatility.

This economic stability is particularly beneficial in long-term planning and budgeting, ensuring that industries can maintain competitiveness in a market that increasingly values sustainability and cost efficiency. By strategically implementing heat recovery-exchangers, industrial facilities can significantly bolster their economic performance while advancing sustainability objectives.

Conclusion

Heat recovery exchangers are crucial in reducing operational costs and enhancing sustainability in modern industries. By capturing and repurposing waste heat, these systems can significantly lower energy consumption, reduce greenhouse gas emissions, and minimise the need for additional resources. Their efficiency makes them a key component of energy-conscious operations, enabling industries to maintain cost-effective practices while contributing to environmental preservation. As industries seek innovative ways to improve energy efficiency and sustainability, heat-recovery exchangers will remain essential for achieving long-term economic and ecological benefits.

FAQ’s

What is a heat recovery exchanger?

A heat recovery exchanger is designed to capture and transfer waste heat from one system to another. This process allows industries to reuse energy that would otherwise be wasted, lowering operational costs and reducing the environmental impact.

How do heat-recovery exchangers save money?

By recovering waste heat and repurposing it within the system, heat-recovery exchangers reduce the need for additional energy consumption, lowering utility bills. This makes them a cost-effective solution for businesses looking to optimise their energy usage.

Are heat-recovery exchangers suitable for all industries?

Yes, heat-recovery exchangers can be implemented in various industries, including manufacturing, chemical processing, and HVAC systems. Their versatility makes them a valuable tool for industries seeking to improve energy efficiency.

Can heat-recovery exchangers be retrofitted into existing systems?

Yes, many heat-recovery exchangers are designed to be retrofitted into existing industrial systems, making it easier for companies to upgrade their energy efficiency without significant overhauls.

How do heat-recovery exchangers improve sustainability?

By reducing the amount of energy required from external sources, heat-recovery exchangers contribute to sustainability by lowering carbon footprints and decreasing greenhouse gas emissions, helping industries comply with environmental standards.

| Related Business Listings |

| Contact Directory |

| Local Business Profiles |