GV Mold has earned its reputation as a trusted partner for businesses seeking to bring innovative plastic products to market. With expertise in design, tooling, and manufacturing, GV Mold provides end-to-end solutions that cater to a wide range of industries, including automotive, electronics, housewares, and industrial applications. Their commitment to precision and quality ensures that every product meets the highest standards while aligning with the unique needs of their clients.

Expert Product Design and Iteration

The design phase is the cornerstone of successful product development, and GV Mold excels in this critical stage. Their team of skilled designers and engineers collaborates closely with clients to create innovative plastic products from the ground up. Using advanced CAD software and reverse engineering techniques, they develop precise 3D models tailored for manufacturability. Whether starting with a new concept or refining an existing design, GV Mold ensures that every product is optimized for functionality, aesthetics, and production efficiency.

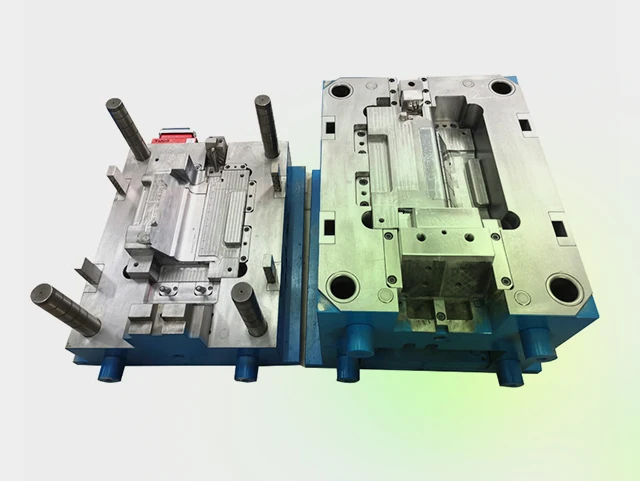

Precision Tooling for Reliable Manufacturing

Tooling is a vital aspect of plastic injection molding, and GV Mold’s expertise in mold building sets them apart. They specialize in creating intricate metal molds designed to precise specifications, ensuring high accuracy and repeatability during production. By employing CNC machining and selecting high-grade steel materials, GV Mold produces durable molds capable of handling large-scale manufacturing runs. This attention to detail in tooling construction guarantees consistent quality across all batches, custom plastic injection mold making it a cornerstone of their operations.

Leveraging DFM and Mold Flow Analysis

GV Mold integrates Design for Manufacturing (DFM) and Mold Flow Analysis (MFA) into its processes to streamline production and minimize defects. DFM ensures that product designs are optimized for manufacturability by addressing potential issues such as warping or sink marks early in the development phase. MFA simulates the flow of molten plastic within molds, predicting challenges like uneven cooling or air pockets. Together, these methodologies enhance productivity, reduce waste, and ensure consistent results across all production cycles.

Material Selection for Enhanced Product Performance

Selecting the right material is crucial for ensuring the functionality and durability of plastic components. GV Mold provides expert guidance in choosing materials based on specific application requirements such as strength, flexibility, heat resistance, or chemical compatibility. For example, they recommend wear-resistant polymers for industrial applications or BPA-free plastics for housewares. By aligning material properties with functional needs and sustainability goals, GV Mold ensures that every product performs reliably while meeting cost considerations.

Early Supplier Involvement for Better Results

GV Mold advocates for Early Supplier Involvement (ESI) as a strategic approach to enhance product development. By integrating suppliers early in the design phase, they foster collaboration that leverages supplier expertise on materials and manufacturing processes. ESI reduces costs associated with late-stage modifications while improving communication between stakeholders. This proactive strategy enhances risk management and accelerates decision-making, resulting in competitive products that meet market demands efficiently while maintaining high standards of quality.

Tailored Solutions Across Industries

GV Mold’s ability to deliver customized solutions makes them an ideal partner across diverse industries. For automotive applications, they produce lightweight yet durable components that improve vehicle performance and fuel efficiency. In electronics manufacturing, their expertise ensures precision in intricate connectors and housings. For housewares, ergonomic designs combined with aesthetic appeal provide functional yet visually pleasing products for consumers. This versatility allows GV Mold to meet the distinct needs of each sector effectively while maintaining top-tier quality standards.

Why Choose GV Mold as Your Partner?

GV Mold’s comprehensive approach makes them a preferred choice for businesses seeking reliable plastic injection molding solutions. Their ability to provide end-to-end services—from concept development to full-scale production—ensures seamless execution at every stage of a project. By combining technical expertise with innovative methodologies like DFM/MFA integration and early supplier involvement, GV Mold delivers products that exceed expectations while helping clients optimize their manufacturing processes.

With its dedication to precision, reliability, and innovation, GV Mold continues to lead the way in bringing groundbreaking plastic products to market efficiently and effectively in today’s competitive industries.