Is it possible to get a 10000-litre slimline water tank?

Our fluid category 5 break tank for potable and non-potable water are all fully DWI approved and meet the specific requirements of Regulation 31. For chilly water storage cisterns and design suggestions for mains supply inlets. If we look at the technical details of those tanks; We see that its weight is one hundred eighty kilograms, its top is 240 centimeters, and its materials thickness is 10 millimeters. In the sleeve part, a brass sleeve is used to ensure its suitability for food. Usage temperature rates are between the coldest -5 degrees and the hottest +50 degrees. In addition, the lid half is also produced using polyethylene uncooked materials by method of its suitability for meals.

White Sintex Pure Antimicrobial Water Tank

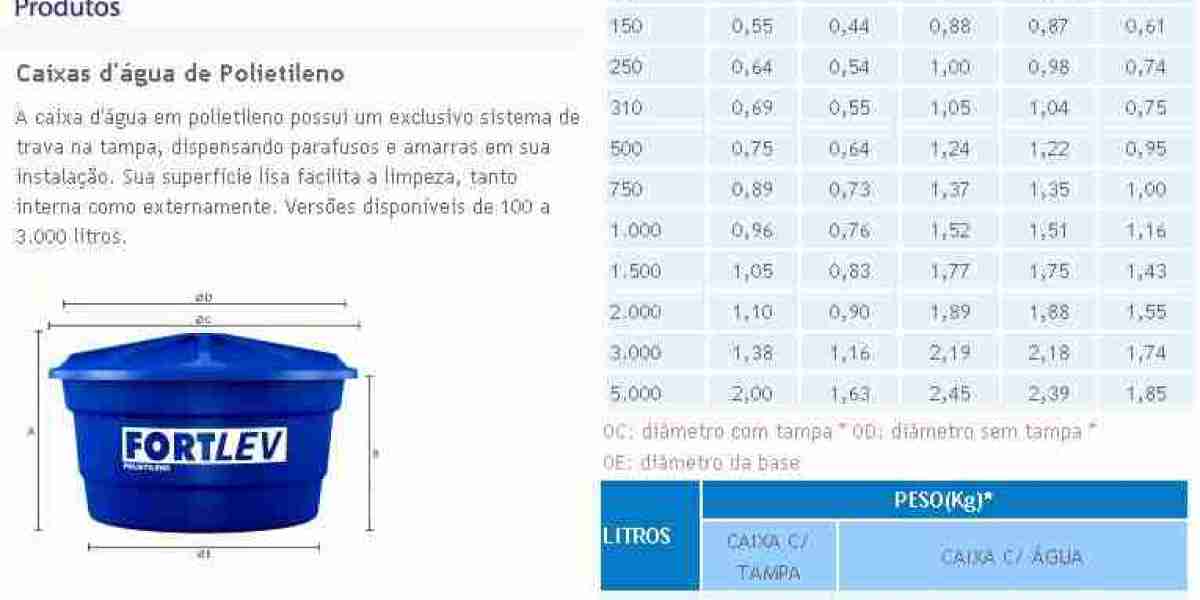

Tank-Mart.Com is proud to be America's largest supplier and distributor of plastic storage tanks, together with low profile holding tanks, custom water storage tanks, and more. We provide tanks in a spread of supplies, corresponding to PVC, metallic, and polyethylene. We also stock leading manufacturers, together with Norwesco, Snyder, and Ronco. These tanks are produced using polyethylene uncooked supplies. The chemical language name of those shops is linear low-density polyethylene "LLDP". The tanks produced utilizing this uncooked material have many advantages provided to the user.

Standard Inclusions

In this context, polyethylene has two essential properties. Our 10,000-liter water tanks are the ideal answer for varied functions. Whether it’s for rainwater storage in rural areas or water needs in the trade, our tanks present reliability and effectivity. Our state-of-the-art manufacturing amenities never use recycled raw materials from recycled scrap or colorants that injury the tank. These tanks, that are produced with quality raw materials, are longer lasting, dependable and more sturdy.

000 Litre Water Tank: FAQ’s, Frequently Asked Questions

These rainwater filters have 2 inlets for incoming water which are 4? The Tank Shop Ltd have over 20 years experience selling tanks on-line and have constructed a status for value, honest recommendation and first-class customer support. We are pleased with our monitor document and only work with one of the best producers in the UK & Germany, so that you could be positive everything we promote is top quality. There are many on-line stores round however The Tank Shop is the best reseller. If you are an owner of a water tank in want of servicing, get in contact with our service team and we'll take care of you.

ELEVATED WATER TANKS & TANKS ON TOWERS GALLERY

Depending on the situation and measurement of the inhabitants, water towers can value up to $8 million to build. The emergency system additionally ensures firefighters at all times have sufficient water stress at hydrants. Cities can extra simply meet the minimal necessities for their firefighting units by utilizing water towers. In some situations, they'll even decrease insurance coverage rates for residents and enterprise owners.

Pumps and Controllers

Then, by encasing the entire affair in some four-inch PVC pipe I happened to have left over from another project. The plumbing system which resulted was very strong and has proven to be nearly freeze-proof. I hooked up my block and tackle–which consisted of two double blocks and 200 toes of half-inch rope–to a spot fifteen feet up on a close-by (and large) tree. From that attachment point the sort out was prolonged down and hooked up to a rope tied round one of many tower’s high sills (Fig. 6) . And the free end of the 200-foot rope was led from the tree to the trailer hitch on my pickup truck. I began by constructing my tower in two equivalent halves–a front and a back–right on the bottom. For this part of the project, I worked from an overview drawing (which had main dimensions to scale) much like the sketch shown in Fig.

These characteristics tend to show vital performance benefits in low strain and Tradersreview.Co.uk low irrigation rate purposes. Sieve trays are simply steel plates with holes in them. Vapour passes straight upward through the liquid on the plate. The association, quantity and dimension of the holes are design parameters.

Virtual tour of the operation unit

The reflux stream is important not only to reduce back the variety of trays required for a specified separation, but additionally be the source of liquid flow required for the enriching section. The liquid faraway from the reboiler is named bottom product. The variety of trays required with a distillation column or column top for a specified separation depends on both the thermodynamic vapour-liquid equilibrium of the system and tray hydraulics. Despite many various tray designs available commercially, distillation column usually needs more plates than the number of equilibrium levels, as mass switch limitations and poor contact efficiency stop equilibrium being achieved on a plate. As a result, evaluating column efficiency and hydraulic traits is of nice significance for each distillation column operation and design.

The actual variety of phases required for the separation additional is determined by the general column effectivity or stage effectivity, which in turn is dependent upon operation situations along with the mechanical design of the column internals. In general, excessive stage efficiency requires excessive liquid flow fee on the tray to maintain up a deep pool of liquid for lengthy contact time. High vapour velocity can additionally be essential to generate sufficient bubbling and excessive interfacial space for vapour-liquid contact, and so high stage efficiency as shown in the efficiency diagram in Figure 2.6. In distinction, low vapour and liquid flow charges typically lead to low effectivity due to brief contact time and weeping in instances such as sieve tray. However, at high vapour velocity, small droplets of liquid may be carried up by vapour to the highest tray, causing sufficient entrainment and even flooding, and far decreased stage effectivity. As well, high vapour flow fee and deep liquid level on the tray both end in excessive pressure drop for the vapour to move by way of the tray.

Structured Packed Towers

On the other hand, packings are utilized in lower liquid rate applications (less than 50 m3/m2-h), particularly when minimizing pressure drop throughout the column is desired. They present a great amount of surface area per unit quantity to facilitate the vapor-liquid mass switch. Unlike the stepwise contact in distillation trays, a packed mattress allows for continuous contact between the vapor and the liquid on the surfaces of the packing. A tray column is to be used to separate ethanol-water mixture from an ethanol fermentation stream at 750 L/h with 20 vol% ethanol. The feed is to be introduced to the column as subcooled liquid at 25°C. It is intended to use a single column to complement ethanol to 80% by mole, and the molar focus of ethanol at the bottom should be lower than 1.0%.

Common Types of Distillation Trays

Because of the CMO assumption, both liquid and vapour circulate charges stay constant throughout the tray. As properly, the vapour leaving the tray with composition $ y_n $ is taken into account to be in equilibrium with liquid leaving the tray with composition $ x_n $. The plate distillation column stands at a peak of __ and a diameter of eleven.87 inches. There are 12 plates within the column where, from the bottom-up, there are four sieve trays, four ballast trays, and four bubble-cap trays. A pump is used to feed the streams into the column and there are pumps on the condenser and reboiler (to overcome head loss).