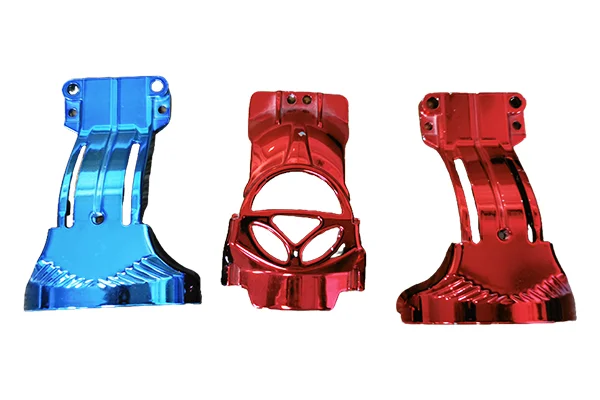

In today’s rapidly advancing industries, the demand for materials that combine strength, durability, and resistance to harsh environments has never been greater. One such material solution is the Aoke Aluminum Alloy Die-casting Anode. This advanced component is recognized not only for its robust performance but also for its versatility across multiple applications. With its superior corrosion resistance, wear resistance, and refined appearance, the aluminum alloy die-casting anode has become an essential choice in automotive, electronics, machinery, and construction industries.

What is an Aluminum Alloy Die-casting Anode?

An aluminum alloy die-casting anode is a specialized component manufactured through precision die-casting techniques. By using high-quality aluminum alloys, the anode delivers excellent mechanical properties and a fine surface finish. The die-casting process ensures consistent dimensions, smooth edges, and high structural integrity, making it suitable for demanding industrial environments.

The main function of this anode is to provide long-lasting protection against corrosion, particularly in systems exposed to moisture, chemicals, or saltwater. Its ability to extend the service life of equipment makes it a preferred choice in industries where performance and reliability are non-negotiable.

Key Features of Aluminum Alloy Die-casting Anode

Superior Corrosion Resistance

Aluminum alloys naturally form a protective oxide layer, and when combined with die-casting technology, the anode achieves excellent resistance to corrosion. This ensures reliable performance in marine, industrial, and outdoor environments.

High Strength and Durability

The aluminum alloy die-casting anode offers superior mechanical strength, enabling it to withstand high loads, vibration, and impact. This makes it suitable for heavy-duty applications such as automotive engines and construction machinery.

Excellent Wear Resistance

With outstanding resistance to wear and abrasion, the anode maintains its functional integrity even under constant friction or harsh conditions.

Lightweight with Aesthetic Appearance

Aluminum alloy is known for its lightweight properties, reducing the overall weight of machinery and devices without sacrificing performance. Additionally, the die-casting process creates a smooth, attractive surface that enhances product appearance.

Cost-Effective Solution

Thanks to the efficiency of die-casting production, the aluminum alloy die-casting anode provides both performance and affordability. Its long service life further reduces maintenance and replacement costs.

Applications of Aluminum Alloy Die-casting Anode

The versatility of this anode makes it suitable for a wide range of industries:

Automobile Industry

Used in car engines, transmissions, and other components, the anode ensures corrosion resistance and extended service life of critical automotive systems.

Electronics

In electronic housings and components, aluminum alloy die-casting anodes protect delicate circuits from corrosion and environmental damage.

Machinery

Heavy-duty industrial machinery often operates in demanding environments. The anode provides robust protection, ensuring reliability and reducing downtime.

Construction Industry

In architectural structures, bridges, and infrastructure, aluminum alloy die-casting anodes contribute to both durability and aesthetics, supporting long-term structural stability.

Marine Applications

Particularly effective in saltwater environments, the anode prevents corrosion in ships, offshore platforms, and marine equipment.

Advantages of Choosing Aluminum Alloy Die-casting Anode

Long Service Life: Prolongs the lifespan of equipment by reducing corrosion and wear.

Low Maintenance: Minimizes the need for frequent replacement or repair.

Eco-Friendly: Aluminum alloys are recyclable, contributing to sustainable production.

Precision Manufacturing: Die-casting ensures dimensional accuracy, enhancing product quality.

Versatility: Adaptable to a wide range of industrial and commercial applications.

Why Industries Trust Aluminum Alloy Die-casting Anodes

Modern industries demand solutions that strike a balance between cost efficiency and superior performance. Aluminum alloy die-casting anodes meet these demands by offering high strength, excellent anti-corrosion properties, and adaptability across multiple sectors. Their reliability reduces the risk of system failure, helping businesses maintain consistent operations while saving on long-term costs.

Conclusion

The Aluminum Alloy Die-casting Anode stands as a symbol of innovation and practicality in today’s industrial landscape. With its superior corrosion resistance, outstanding wear resistance, lightweight nature, and aesthetic appeal, it is an indispensable component across various industries. Whether in automobiles, electronics, machinery, construction, or marine equipment, this anode continues to deliver exceptional value and performance.

For businesses looking for durable, cost-effective, and environmentally responsible solutions, the Aoke aluminum alloy die-casting anode is the ideal choice.

https://www.aoprecision.com/aluminum-alloy-die-casting-anode-with-superior-strength.html