Rice is one of the most important staple foods worldwide, and behind every grain of perfectly polished rice lies advanced technology and specialized tools. Among these, the rice rubber polisher plays a vital role in ensuring high-quality rice with a glossy finish, minimal bran residue, and reduced breakage. But for rice millers, the real challenge is finding the right Rice Rubber Polisher Manufacturer one who offers durability, consistency, and value for money.

In this blog, we’ll cover everything you need to know about rice rubber polishers, what makes a reliable manufacturer, and highlight some of the top suppliers in the industry.

What is a Rice Rubber Polisher?

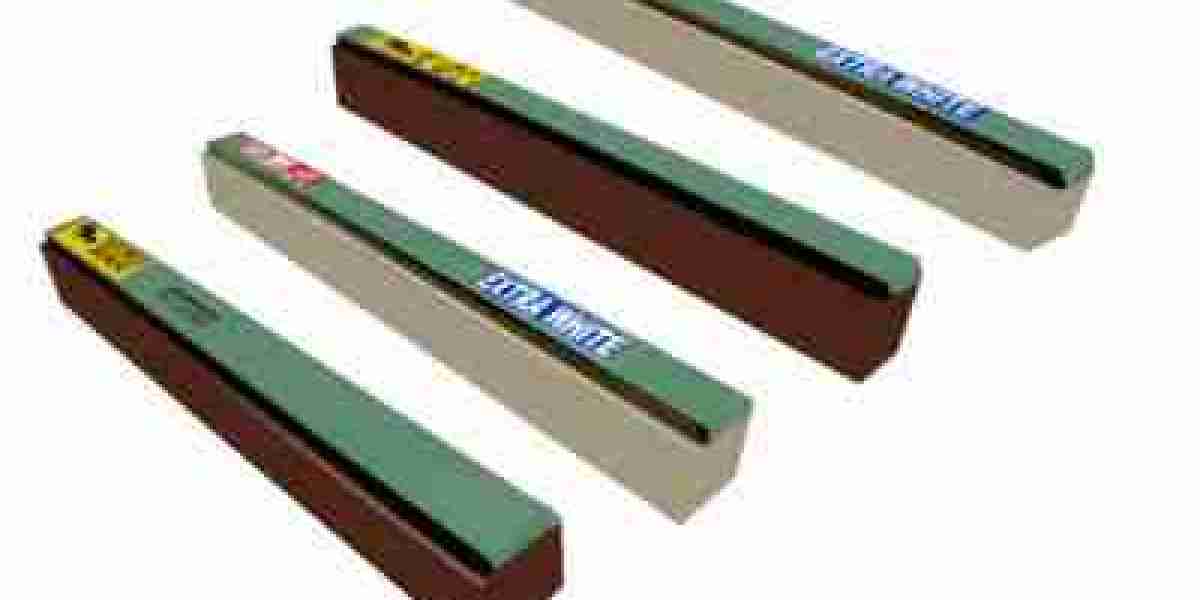

A rice rubber polisher is a critical consumable used in the rice milling process. It is usually made from a blend of natural and synthetic rubber compounds, designed to withstand abrasion and high friction during polishing.

When rice passes through the milling chamber, these rubber polishers gently rub the grains, improving their surface finish. The result is rice that is:

Whiter and shinier

Free from excess bran particles

Less prone to cracking or breakage

More appealing in appearance and texture

These rubber polishers come in different sizes, hardness levels, and designs—some grooved, some plain—depending on the type of rice being processed (raw, steamed, or parboiled).

Why Choosing the Right Manufacturer Matters

Selecting the right rice rubber polisher manufacturer is not just about cost—it directly impacts the milling efficiency, rice quality, and long-term profitability of your rice mill.

Here’s why a reliable manufacturer makes a difference:

Quality Assurance – Well-known brands ensure their products meet industry standards, offering consistent hardness and durability.

Material Strength – The right compound mix (natural rubber + SBR/NBR) ensures long life and heat resistance.

Customization – Top manufacturers offer customized polishers to suit specific milling machines.

Reduced Breakage – A well-designed polisher keeps broken grains at a minimum.

Cost Efficiency – While cheaper polishers may seem attractive, they wear out quickly, costing more in the long run.

Key Features of a Good Rice Rubber Polisher

When sourcing from a manufacturer, always check for:

Shore Hardness (40–60 A): Determines abrasiveness vs. gentleness on grains.

Size & Dimensions: Must fit your polishing machine perfectly.

Heat Resistance: Prevents wear and tear during long milling hours.

Uniform Performance: Should deliver consistent polishing over its lifespan.

Durability: Longer-lasting polishers reduce downtime and costs.

Top Rice Rubber Polisher Manufacturers

Here are some of the most trusted manufacturers and exporters of rice rubber polishers, known for their global presence and product reliability:

1. Hindustan Group (India)

A pioneer in rice milling accessories, Hindustan Group offers high-quality rice rubber polishers made from natural and synthetic rubbers. Their products are known for durability, minimal breakage, and compatibility with a wide range of polishing machines.

Highlights:

Manufactured using advanced technology

Strong domestic and international presence

Focus on quality and customer satisfaction

2. Shree Balaji Udyog (India)

Balaji is a leading manufacturer and exporter of rice rubber polishers. Their products are designed for raw rice and parboiled rice, with or without grooves. They use hydraulic molding and elastic vulcanized rubber compounds to enhance lifespan.

Highlights:

Available in multiple sizes and specifications

Low maintenance and long-lasting performance

Widely used by Indian and global rice mills

3. Alaska Multipolymers Pvt. Ltd. (India)

Known for their “Duraflex” range, Alaska Multipolymers has been in the rice mill consumables industry for over 50 years. Their rice rubber polishers are ISO-certified and exported to multiple countries.